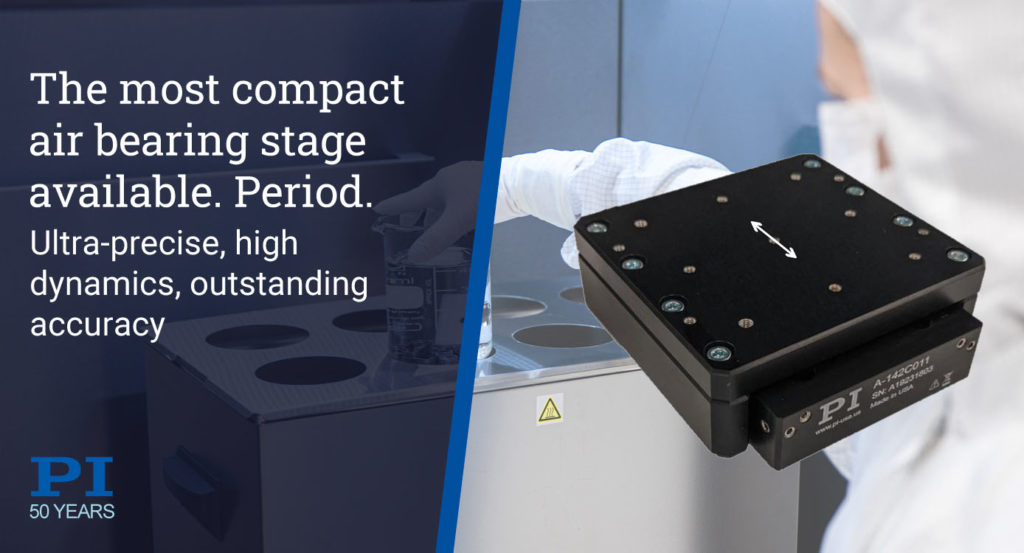

Cleanroom-compatible, this new high performance noncontact miniature linear slide from PI is suited for applications like wafer inspection, scanning/metrology, fiber alignment, laser micromachining and marking, autofocusing, and genome sequencing.

PI’s air bearing motion product line is expanding again. The new A-142 high performance compact nano-positioning and linear alignment stage is designed with a voice coil motor and frictionless air bearing slide for highly repeatable motion with outstanding accuracy. This low-profile nanopositioning stage, only 27 mm high (1.1 inch), is maintenance free, and due to its non-particle generating drive and guiding principle, cleanroom compatible. It delivers 10mm (0.4 inch) of hysteresis-free linear travel of its 75x80mm (≈3×3¼ inch) moving platform while supporting up to 3kg (6.6lbs) loads.

The air-bearing guide guarantees straightness of 100nm and flatness of 0.5µm. High motion performance is achieved with an integrated voice-coil motor that achieves a maximum velocity of 450 mm/s and acceleration of 20m/sec2, a great advantage in dynamic scanning and positioning applications. That’s small and fast! Greater flexibility for alignment and metrology operations in Z is achieved with an optional pneumatic counterbalance to allow vertical mounting without a loss of motor performance. The A-142 can be operated as a standalone nanopositioning device, but for multi-axis motion requirements, combinations and integration into XY and XYZ assemblies are also available.

High accuracy industrial automation processes in fields such as semiconductor test and metrology, genome sequencing, bio-tech, medical engineering, high resolution microscopy, optics and photonics manufacturing.

For more information, visit pi-usa.us.

Leave a Reply

You must be logged in to post a comment.