A number of trends in the motion industry are impacting lead screw design and implementation. One of these is the miniaturization of components. For instance, applications in optics as well as medical devices demand high precision, and smaller miniature lead screws can meet high precision specifications and can fit where space is limited and where larger components can’t be easily accommodated.

Another on-going trend in the motion industry in general has been to offer more application-specific products to end users and motion control system designers. In other words, more customization. Part of what makes this possible is the availability of new materials and new prototyping techniques that can help designers develop and quickly evaluate new components designs.

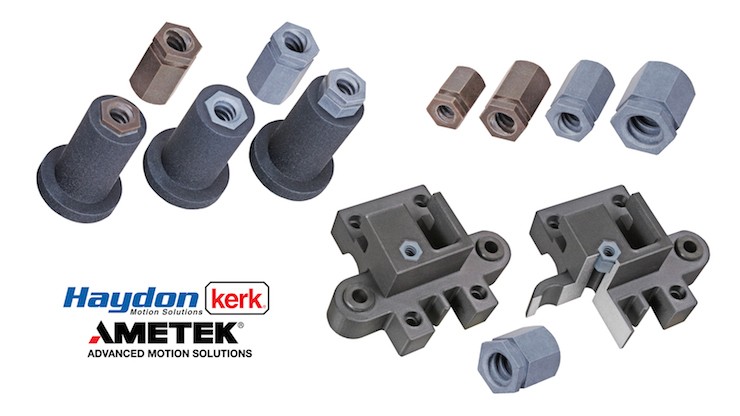

One manufacturer putting new techniques to use is Haydon Kerk. The company now offers 3DP, a premium thread insert for a 3D-printed lead-screw-nut prototype service as a way for machine builders to verify linear-motion design iterations quickly and more accurately.

Engineers typically don’t have access to 3D printers to do this kind of prototyping. Instead, most of them contract with a third party to get quick turnaround on parts. With the new 3DP prototyping services, machine builders can now get help with this type of design verification.

Even in instances in which design engineers do have access to 3D-printing machines, parts produced by such machines are often unsuitable for motion-axis verification. That’s because a major challenge in motion control (particularly lead-screw assemblies in which one surface slides on another) is the materials commonly available for additive manufacturing aren’t designed with tribology that is suitable for power transmission.

Those materials commonly exhibit high friction and poor wear characteristics because they are primarily formulated for mechanical or part-geometry stability. Useful prototyping of a lead-screw-driven axis, however, relies on accurate simulation of the lead-screw-nut assembly’s tribological performance, as this directly impacts power consumption and anticipated life.

The lead-screw-nut inserts have a threaded interior (with a high-efficiency thread form) and a hex-shaped exterior to embed into flanged nut bodies or into more-complex 3D-printed prototype assemblies. In addition to the hex shape, which radially locks the insert into the nut body or assembly, each insert also includes a ring groove that, with adhesive, axially locks it into place.

The 3DP nuts support OEMs that use additive manufacturing for short lead times. These nuts are made of advanced materials that are engineered explicitly for production-part performance. That means the nuts transmit power in a way that’s more representative of how standard volume parts will operate under load, which in turn boosts design-verification accuracy.

Currently, the 3DP nut inserts are offered in a lubricated polyacetal or a proprietary Kerkite KN30, a self-lubricating, high-performance engineered polymer.

OEMs that ultimately arrive at a successful design iteration after using 3DP inserts may then source their production leadscrew components from Haydon Kerk in bulk quantities — in forms that include nuts machined from the same composite material as the 3DP offerings or, for higher volumes, custom nut components molded as complete monolithic plastic pieces, with metal features overmolded into the design where needed.

Leave a Reply

You must be logged in to post a comment.