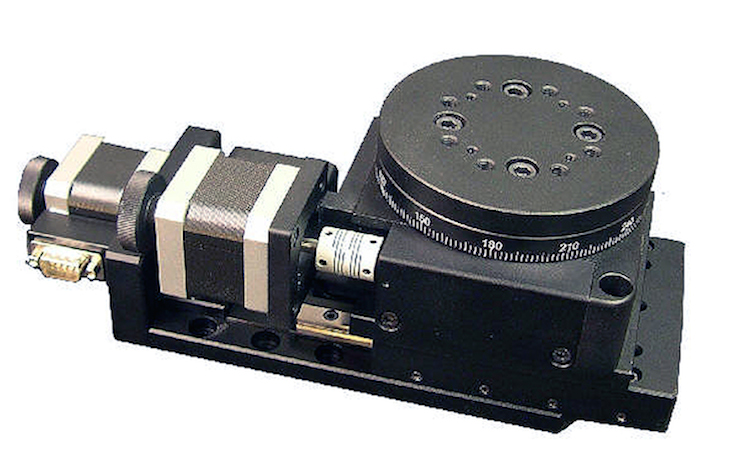

Optimal Engineering Systems, Inc. (OES) has released a new series of high precision X-axis stages with integral rotary positioning stages. The four X-and-theta stages in this series feature linear travels of: 15 mm (0.591 in.), 30 mm (1.181 in.), 50 mm (1.968 in.) and 75 mm (2.953 in.). The rotary table is capable of continuous 360 degree rotation in either direction and measures 100 mm (3.937 in.) in diameter. A 60 mm (2.362 in.) diameter version is also available.

The X-axis stages move on high precision crossed roller bearings and are driven by a 1 mm per turn precision ground lead screw at speeds up to 5 mm/sec. Featuring 3 micron repeatability, the linear resolution of the X-axis stages are 0.5 microns (10 micro-steps per step motor driver in use) and 0.25 microns (20 micro-steps per step motor driver in use) with positional accuracy of 10 microns.

The 100 mm diameter theta stage is driven by a precision 180:1 ratio worm gear. Resolution of the theta stage is 0.001 degrees (10 micro-steps per step motor driver in use). Repeatability is 0.005 degrees, positional accuracy is 0.01 degrees and backlash is 0.005 degrees. A precise pattern of threaded holes in the table simplifies installation of tooling. Two-phase stepper motors are standard. A knob for manual adjustments on each of the stepper motors can be replaced with an incremental encoder for position verification or a servo motor. These compact, black anodized aluminum X-and-theta stages are easy to integrate into new or existing systems. Compatible motion controllers are available from OES and the X-plus-theta stages can also be ordered as complete plug-and-play systems.

These high resolution, high repeatability X-and-theta stages are suitable for applications such as angular glass cutting and grinding, wafer alignment, semiconductor handling, laser cutting, drilling, machining, scanning, inspection, assembly, and testing.

For more information visit www.oesincorp.com.

Leave a Reply

You must be logged in to post a comment.