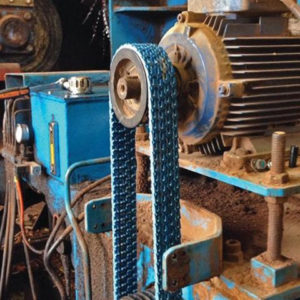

Combining excellent service and long life with exceptional inventory control, the new Wedge Link Belting from Fenner Drives yield major advantages in power transmission drive belt installation and maintenance. Incorporating the industry-proven narrow-wedge design, the 3V and 5V link belts now provide a way to get the benefits of link belting on wedge belt drives. Profiles include 3V, 5V, SPZ, SPA and SPB.

The new products’ individual polyester/polyurethane link design enables belts to be made to any length on-site by hand, making it possible to drastically reduce inventories of fixed-length belts. This easy preparation can be done in short order because the modular method of construction eliminates the need for inventories of conventional belts. Assembly consists of simply reeling off the required lengths of belting and utilizing the twist-lock design to complete the new belt.

Converting to these products, Gabler said, saves substantial time and money on  belt maintenance, repair and replacement wherever they are used.

belt maintenance, repair and replacement wherever they are used.

This long-lasting upgrade to rubber wedge belts combines the performance of rubber with the additional cost-saving benefits and is appropriate for a wide range of applications, including metals production, cement and aggregate industries as well as forestry. These are the only link belts made with this narrow-wedge profile.

Fenner Drives

www.fennerdrives.com

Leave a Reply

You must be logged in to post a comment.