PI’s two new series of direct-drive linear modules are geared for machine builders and system integrators. The V-855 and V-857 product families were designed for high-load and high duty cycle industrial precision motion applications where traditional actuators or linear slides with lead-screw or timing-belt drives are not precise, robust or reliable enough. The maintenance-free and friction free high-speed linear motors mean greater productivity with shorter cycle times and faster return on investment. The new, ready-to-install linear motor modules are beneficial for all high-performance applications, where positioning or scanning with smooth, vibration free motion, minimum tracking errors, and short settling times are required.

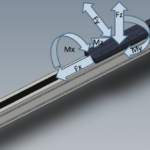

The new closed-loop linear slide module/actuator product families provide high load capacity to 220 lb (1,000 N) and large travel ranges up to 47 in. (1,200 mm) with highly repeatable minimum incremental motion of 100 nanometers. Position feedback is via integrated linear encoders, available down to 1-nm resolution.

Acceleration is as rapid as 5Gs and top speeds of 196 in./sec (5 m/sec) can be reached. Because of the play-free and backlash-free direct-drive mechanics, settling times are extremely short, and bidirectional repeatability is excellent.

For X-Y applications, the V-855 and V-857 linear modules can be stacked orthogonally. For XYZ applications, PI offers the V-817 stage family. PI provides EtherCAT-based high-performance industrial motion controllers – up to 8 axes can be operated from one 19-in. rack and EtherCAT makes it easy to add more.

Applications include industrial precision automation for electronic assembly of sensors, cameras, and optics; metrology and non-contact inspection (X-ray and optical); semiconductor wafer positioning, wafer processing and inspection; automated laser micro-machining and welding, laser cutting, testing and sampling systems for medical equipment.

For more information, visit www.pi-usa.us/en.

Leave a Reply

You must be logged in to post a comment.