June 23, 2017 update: NB Corp. of America will be showcasing the new eXrail at SEMICON WEST 2017 — to be held July 11 to 13 in San Francisco. Here’s a preview of the eXrail:

To see the actual product, visit NB’s booth 5244 at SEMICON WEST. The manufacturer is also offering free SEMICON WEST tradeshow passes. Get your pass complements of NB Corp. by registering here.

Due for release later this year, a linear bearing called the eXrail from NB Corp. of America is a linear guide rail using recirculating needle rollers to support loads over linear strokes. It’s useful in applications needing high precision (such as medical equipment, for example) thanks to high rigidity and motion accuracy — as well as the ability to damp vibrations.

NB Corp. of America has released a fun video on the product — with an animation in which the “eXrail transforms into eXrail-1 to fight against the evil forces of fire, oil, and heavy metals” to protect slide guides from premature failure, according to playful manufacturer literature on the product:

Core to the eXrail linear guide’s performance are specialized needle-roller bearings; precision surfaces; and a specialized lubrication system.

The eXrail incorporates needle rollers to reduce deformation and is equipped with three types of seals.

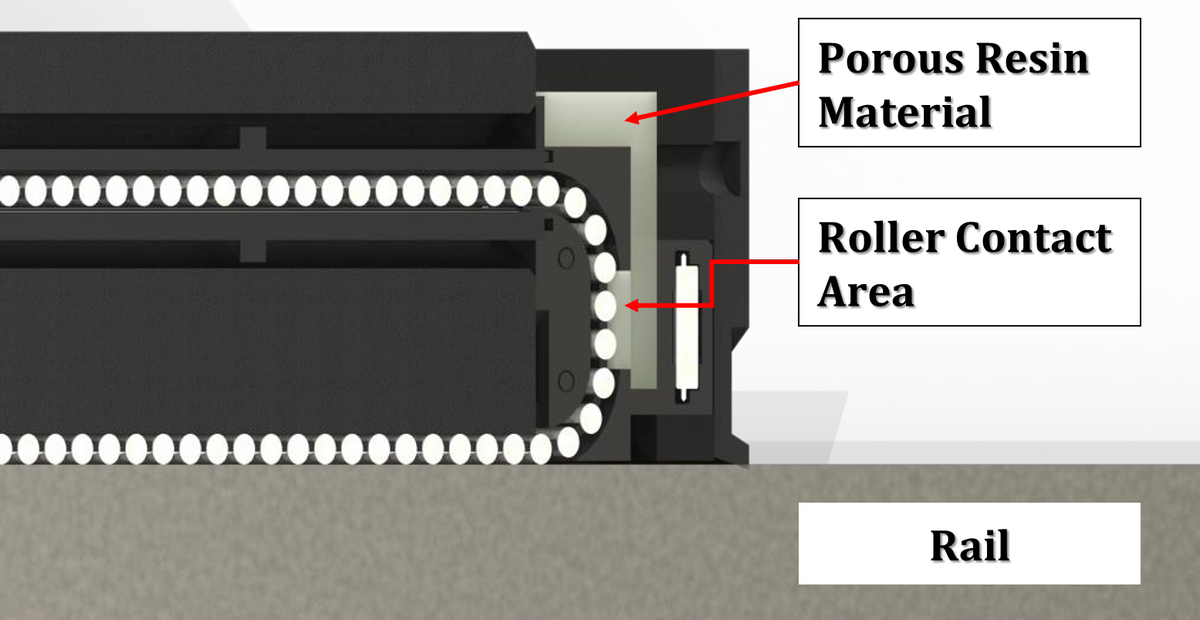

The block sports a porous resin material soaked in oil to extend the time between maintenance …

… So when installed on linear-motion axes, the linear guide satisfies industry demands for guides and linear bearings that are accurate and easy to maintain.

Linear-bearing self-lubricating function: NBʼs eXrail has a porous resin material soaked in lubrication oil to extend maintenance intervals.

There are oil holes in three directions to give end users more flexibility for relubrication work.

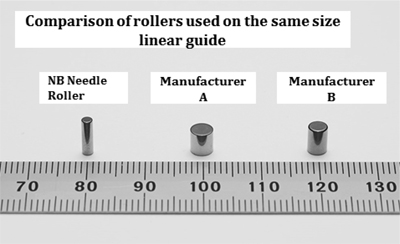

Linear-bearing needle rollers: Because linear guides affect the quality of the end product, the eXrail has longer slim-type needle rollers. More specifically, NBʼs needle rollers have half the diameter of conventional rollers — and are longer as well. Longer rollers mean increased contact area … and that in turn reduces contact pressure. Plus because the rollers are half the diameter, more rollers can fit in a given space.

Within a linear-bearing block with conventional rollers, contact with the roller guide is focused on a small area — with high pressure concentrated on a small space.

Within a linear-bearing block with NB’s needle rollers, contact with the roller guide is more spread out. So even though the block may carry the same load, the rollers distribute pressure more evenly.

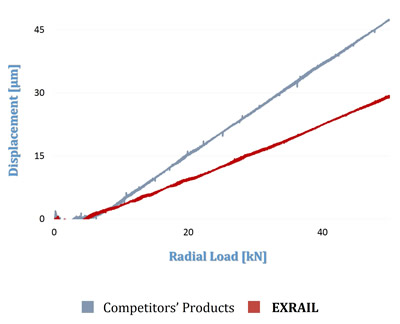

Another benefit to the linear bearing design is higher rigidity.

Thanks to the needle rollersʼ reduced diameter, more rollers fit into the block volume. Because they distribute load more evenly, there’s less elastic deformation when carrying heavy loads. This in turn equates to 150% more rigidity than conventional linear bearings.

Stay tuned to linearmotiontips.com for more on this technology, and leave any comments or questions below.

Leave a Reply

You must be logged in to post a comment.