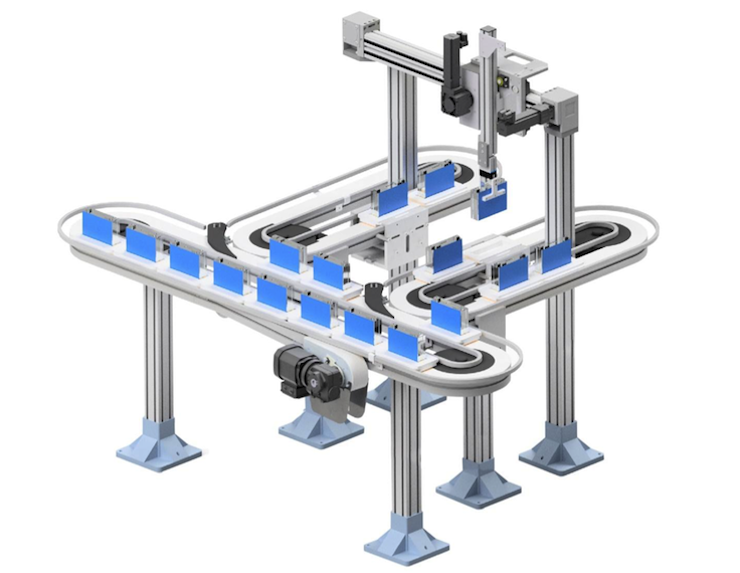

mk North America’s new pallet conveyor system, the VersaFlex P08, is designed to quickly be altered and adapt to product changes. It can also convey products that have unusual shape or geometry with ease.

VersaFlex P08 carries loads up to 22 lb per pallet and can carry multiple pallets at once. It also boasts repeat accuracy of ± 0.1 mm when used with mk’s stops and locating devices. The pallets are guided by side rails and can be customized and equipped with features that accommodate all types of unique parts – from automotive, metal working, assembly as well as battery and fuel cell lines.

“Our team is excited to expand our VersaFlex product offering with the new addition of the P08 pallet system. The P08 system allows for maximum product versatility in an automation environment while also maintaining an efficient and economical footprint for our customers and end-users alike,” said Scott Blais Jr., Inside Sales Manager at mk North America.

Features of the P08 Pallet-Handling Conveyor system include:

Pallet Width: 150 mm

Pallet Length: 150, 200 or 250 mm

Frame Width: 85 mm

Chain Width: 83 mm

Conveyor Length: up to 30 m

Load: Up to 22 lb per pallet

Speed: Up to 165 fpm; constant or variable speed options

Voltage: All standard US, Mexico and Canadian voltages

Pallet Handling Devices: Pallet Stops, Lift and Locates, and Pallet Diverters

mk North America’s VersaFlex flat top chain conveyor system is ideal for complex layouts and features simple and fast configuration and commissioning possibilities. It’s also suitable for all industries and compatible with existing systems. The P08 pallet-handling conveyor system also works in conjunction with the company’s other pallet-handling systems and is a great option for pallets that are too small and light for VersaMove.

For more information, visit www.mknorthamerica.com.

Leave a Reply

You must be logged in to post a comment.