by Mark Huebner, PBC Linear

Minimize corrosion and maximize the life of linear roller bearing systems by following a few simple guidelines on lubrication.

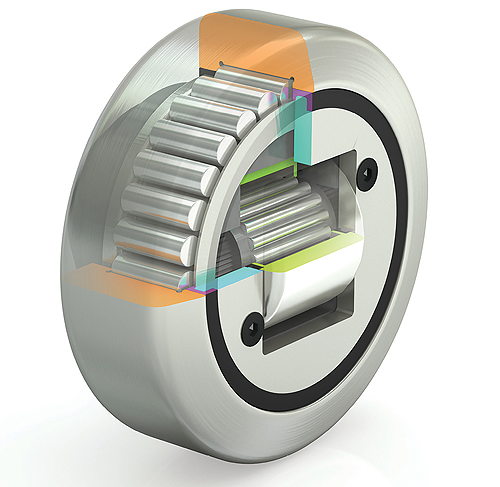

Linear roller bearing systems offer distinct advantages in applications requiring high speed or quick change of direction. Because their diameter is larger, they also perform well in contaminated environments where they roll over or “push” particulate from the raceway. However, due to the nature of the design having both steel bearing races and a steel linear raceway, lubrication must be present to minimize the results of metal-to-metal contact and extend the life of the system.

Internal roller lubrication

For instance, some smaller diameter rollers in the PBC line are internally lubricated for long life. No additional lubrication is necessary for the internal rolling elements of the bearing. The rollers are sealed (or shielded) against the operating environment to prevent the egress of lubricant and the ingress of contaminants. Some larger rollers can be supplied with a grease access point and the internal components can be re-lubricated using a zerk fitting.

Raceway/guideway lubrication

To ensure long life, it’s necessary to have a thin film of lubrication on the raceway/railway at all times. When properly applied, lubrication does a number of things including:

• reducing wear

• reducing stress on the contact surfaces

• reducing friction (and therefore heat buildup)

• allowing for operation at designed specifications of the product (de-rating is required for un-lubricated applications)

• helping protect metal surfaces against corrosion (rust and fretting corrosion)

Lubrication type

Technical, environmental, ecological and economic factors will determine whether oil or grease should be used in an application. In fact, the environmental is one of the most significant factors when selecting a lubrication type. If extreme conditions are expected, it’s highly recommended that you speak with a representative from the supplier company. This includes heavy contamination, when the expected particle size is smaller than 0.1 mm (0.005 in.) as small particles can more easily bypass seals and wipers.

Another important point to remember is that the compatibility of lubricants must always be checked. This check should be done under both static and dynamic conditions and within the operating environment. Some lubricants may have unexpected, negative reactions with the plastics, elastomers or non-ferrous metals within the products. It’s possible to draw upon previous and practical experience or guidelines from the lubricant manufacturer. When in doubt, consult the lubricant manufacturer.<

Periodic lubrication/maintenance

The lubrication interval is dependent on many operating and environmental conditions, such as load, stroke, velocity, acceleration, mounting position/orientation, type of lubrication used, temperature, humidity and UV exposure. The actual lubrication interval should be determined by tests conducted under actual application conditions.

While the actual lubrication intervals are application specific and determined only through testing, some guidelines can typically be used as a starting reference point under “normal” conditions. For instance, a good rule of thumb is that re-lubrication should be done every 1,000 km, 50,000 cycles or six months, whichever occurs first.

Oil filled polymer lubricator

Some companies use a polymer lubricator. For example, some PBC Linear products offer a high-quality polymer lubricator which is an advanced, oil filled porous polymer that has been tested to show better performance and longer life than similar wiper/lubricators made of oil or grease-filled felt. In some applications, this special lubricator will last the life of the application without additional re-lubrication.

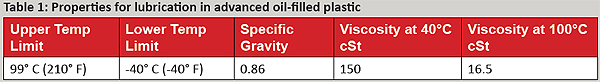

This lubricant within the polymer is NSF registered for both H1 and H2 applications (direct and indirect contact with food). It can also be used for washdown and industrial applications. The lubrication within the polymer contains corrosion inhibitors, anti-oxidants and extreme pressure (E.P.) additives. Table 1 shows some specific properties for the lubricant.

Used lubricants

Used lubricants should be disposed of using environmentally friendly methods. Most lubricant manufacturers have guidelines regarding their allowable storage, use and disposal. In addition, some countries have regulations for these issues for occupational safety and environmental protection. Furthermore, some companies may have adopted internationally accepted quality and standards policies (such as ISO14001), which will further regulate the use of lubricants within an application.

These guidelines and regulations must be followed and care should be exercised as to not specify a lubricant that is forbidden.

Lubrication failure

Contamination and lack of lubrication are the two primary causes of (ball-based) linear guide failures. Lack of lubrication will cause fretting corrosion, which can cause permanent system damage and eventually lead to system failure. Fretting corrosion is a form of damage caused by a combination of corrosion and abrasive wear. Fretting corrosion can typically be seen as a reddish discoloration on either mating raceway (track or roller), which is sometimes confused with rust. Both are signs that additional lubrication is necessary and the re-lubrication period must be decreased.

Operation in an un-lubricated state

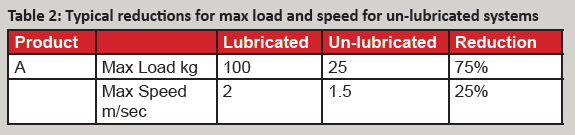

While not recommended, it’s possible to run most systems without lubrication; however, there will be significant reductions to maximum load, maximum speed and expected life. Table 2 shows that a typical un-lubricated system will have a significantly reduced maximum load and a reduced maximum speed when compared to a properly lubricated system.

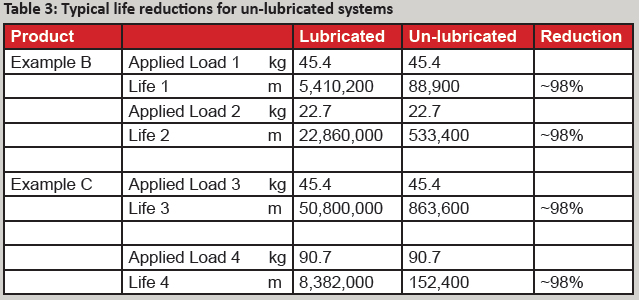

In addition to significant reductions in maximum load and speed, un-lubricated systems will also experience an extreme reduction in expected life. Table 3 shows the expected life for both a lubricated and un-lubricated system for two different products with two different applied loads. The approximate reduction in lifetime has also been calculated.

PBC Linear, A Pacific Bearing Company

www.pbclinear.com

Leave a Reply

You must be logged in to post a comment.