By Chad Carlberg | Product-line manager for linear actuators, Thomson Linear • Today’s electromechanical actuators deliver performance that’s comparable or even superior to other technologies in outdoor applications. They’re often cleaner with lower cost of ownership than predecessors.

Traditional electric actuators provide basic machine functionality (to push and pull loads on command via switches) but more integration of advanced electronics is making today’s linear actuators smarter, safer and easier to network with an array of equipment. Such linear actuators can track parameters remotely and react automatically, making for inexpensive real-time operation and network flexibility. At the core of this new breed of actuator smarts are programmable microprocessors.

Safer operation with condition monitoring

Conventional electric-actuator designs can sustain motor or mechanical-component damage from continuous overloading. Such actuators that fail at unfortunate times can damage equipment or threaten the safety of personnel especially in heavy-duty off-highway applications.

Actuators that sport onboard electronics prevent such incidents by monitoring voltage, current, load and temperature. They safety shut down if any of these parameters exceed critical set points. So if detected temperature is hotter than what the actuator can withstand, the onboard electronics can steer the axis into a safe shutdown.

In a similar way, onboard electronics can also detect unsafe loading. Say an actuator setup to move a 2,000-lb load with 18 amps of current suddenly outputs an amperage that is beyond a factory-calibrated trip point. Here, the actuator’s electronics can shut the axis down at a given safe position. Some electronics even prevent nuisance tripping (and degraded productivity) by letting the actuator run harder in cooler environments.

Actuator electronics improve motion control

Electronics onboard linear actuators give designers enhanced motion control as well. These functions take six forms:

• Low-level power switching. Traditional actuators often need large and power-inefficient relays or independent controllers to retract, extend, and stop. In contrast, onboard electronics manage power so current at switches or contacts goes from 20 A to less than 22 mA for simpler and less costly system design.

• Analog position feedback. With the addition of a noncontact potentiometer, for example, a voltage signal indicates actuator position, speed and direction for more controllability.

• Digital position feedback. One single-channel pulse-signal encoder can synchronize actuators or communicate the position and speed from a single unit.

• Dynamic braking. Where power to an actuator is cut but the load keeps the axis coasting, there’s a threat to repeatability and precision. Conversely, onboard electronics with dynamic braking controls can guide a linear actuator to a precise stop even if power is lost.

• Limit-switch output. Safe and effective actuator operation depends on knowing when the actuator reaches end-of-stroke. So if an actuator functions to lock a device into place, a simple LED light triggered by the output can alert operators when that doesn’t happen — an unsafe condition. End-of-stroke output also helps protects actuators and equipment to which they connect.

• Internal end-of-stroke limit switches. These automatically shut down actuators at ends of travel to make mechanical clutch ratchets at stroke ends unnecessary and maximize actuator life.

SAE J1939 support for actuator flexibility

The SAE J1939 CAN bus communication is a standard gaining traction in agriculture and construction-equipment markets. Using electric actuators with J1939 compatibility lets equipment designers and end users leverage the benefits of J1939-enabled condition monitoring and controls.

Onboard J1939 compatibility lets linear actuators speak the same language as electronic control units (ECUs) already on such equipment. This in turn enables communication across networks running through a twisted pair of wires. In contrast, traditional electric actuators need stand-alone ECUs.

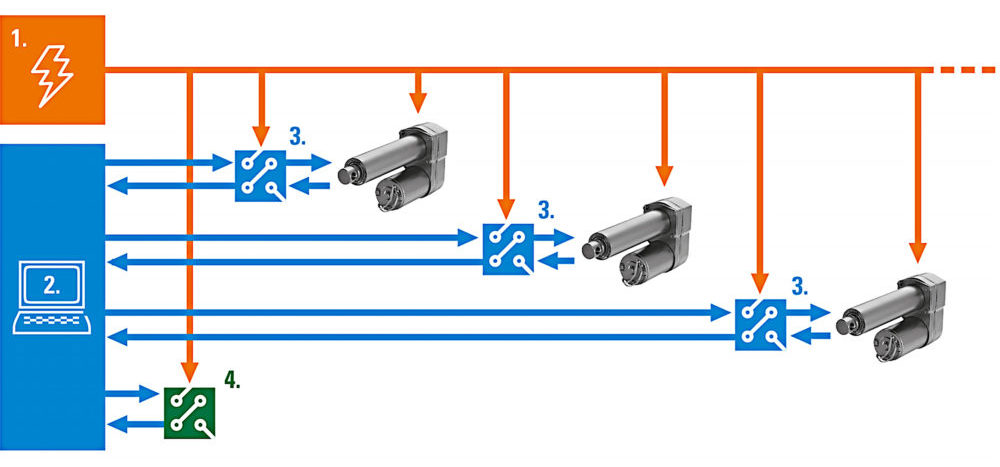

Traditional communication architectures only let actuators connect to ECUs via standalone controls. But smart actuators compatible with the J1939 CAN bus can run in arrays off one main ECU to enable control strategies once too complex for implementation. Such setups also boost flexibility, as a given actuator can work in different applications.

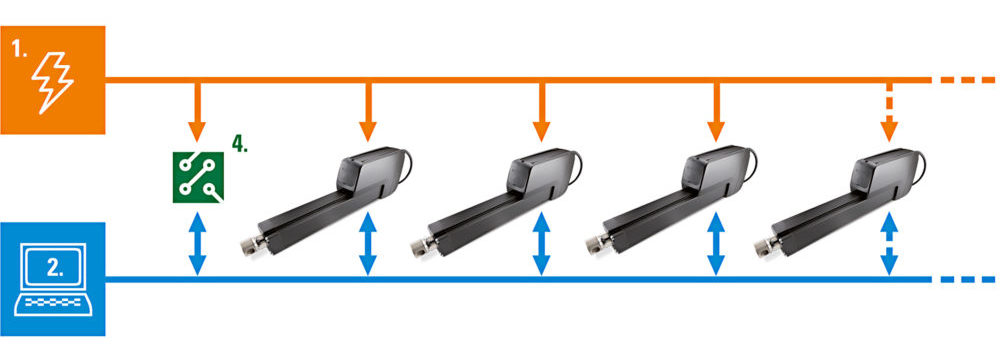

Other benefits of SAE J1939 CAN bus communication compatibility are less wiring and minimized engineering time and cost. Deploying traditional actuators to an ECU took a dedicated communications cable to that ECU, a thick power cable to the equipment battery, and a relay or switch. In contrast, an actuator with onboard compatibility simply connects to the J1939 bus for efficient power-supply connections.

As long as the J1939 CAN bus network stays in use — which is for the foreseeable future — OEMs can incorporate electric actuators into their designs easily and at a fraction of the expense that might have been necessary otherwise. There’s no need for independent controllers, and one actuator model can work in multiple applications.

Another benefit is that J1939 support often lets engineers eliminate a standalone controller. Consider how traditional electric actuators are operated by a stand-alone ECU. A network of actuators with integrated J1939 support only need a single cable run from the controller. Each actuator gets a unique address, listens to every signal from vehicle controls, and responds only to signals designated for its operation. Such smart actuators also feed basic speed and position information (with diagnostics) to the control unit for better automation.

One actuator for several different uses

Consider how some farm-equipment manufacturers strive to use a single actuator model for several applications on a given piece of machinery. One application may need a 2,000-lb push-and-pull force for travel of 6 in., while another may only need 500 lb moved over 4 in. Traditionally these needed completely different actuator designs. Now however, one J1939-compatible actuator might let system engineers program identical units to function specifically to application requirements, drastically cutting engineering time and wiring (not to mention the cost of adding and maintaining a separate controller).

By electronically modifying the stroke length, these engineers can use a given actuator model and housing on an axis with a 500-lb trip point and another axis with a 2,000-lb trip point. One common actuator here makes diagnostics easier (as error monitoring one actuator design is easier than monitoring many types) while simplifying ordering and inventory. Using a single standard actuator also improves leadtime … so installation ultimately takes less time.

Thomson Linear • www.thomsonlinear.com

Leave a Reply

You must be logged in to post a comment.