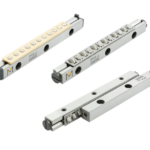

Compact – Smooth – Accurate

PM’s miniature ball slide Type PMM is a compact and robust solution for smooth and accurate linear motion that fits in narrow spaces to transfer light to moderate loads. The slides where developed for the semiconductor industry and medical devices where they are used for accurate positioning of samples under microscopes. The slide consist of high precision finished table parts with integrated raceways. The special designed ball cage provide outstanding performance in terms of smoothness and low friction.

Available sizes and stroke lengths:

PMM miniature linear slides are available in three sizes; PMM 05, 1 and 2. Within a size there are different lengths, varying from 10 mm – 80 mm. The stroke lengths vary between five and 70 mm while the dynamic load capacity is 23 N – 429 N.

Easy mounting

Easy mounting and installation in the application is possible through the standard threaded holes in the center rail and the carriage. The slides are pre-lubricated with a small amount of oil and are ready-to-use.

High runout accuracy with smooth movement

PMM miniature slides are preloaded without backlash. They are preloaded by geometry pairing, using precision balls with a slight oversize of 0.5 microns. This allows the preload and stiffness to be set accurately and guarantees a backlash-free, smooth accurate and repeatable movement. The four-point contact between the balls and the raceway, the high precision ground raceway and the design of the ball cage cause the slide to move very smoothly with very little low friction and low starting force.

Straight line accuracy and flatness accuracy are depending on size and lengths, they range from three to six microns for the standard precision class. Higher specifications to be requested.

Material and Design

The center rail and carriage are made of stainless steel and through-hardened. The ball cage materials are brass and stainless steel. The design of the cage, a U-shaped precision curved strip with ball pockets on both sides, makes it less sensitive to cage creep.

This is a phenomenon whereby the cage slowly creeps out of its original position. In most cases it happened due to a poor alignment of the slide in the assembly, high speeds and accelerations or in vertical mounting orientations. As the cage creeps away from his centered position it prevents the carriage from reaching its maximum stroke. The design of the cage reduces the risk of cage creep.

Miniature slides PMM are used in test rigs, manipulators, microscopy, assembly fixtures, medical instruments and micro assembly lines. Anywhere the space is limited and accurate, smooth and high reliability is required.

Customer-specific solutions

Engineers can request customized versions of the PMM miniature slides that meet individual requirements, example:

- Custom stroke length

- Customized slide width – length

- Cleanroom or vacuum compatible

- Lubrication

- Higher load carrying capacity

- Different hole pattern

- Specified moving force

For more information, visit this deep link at www.pm.nl

Leave a Reply

You must be logged in to post a comment.