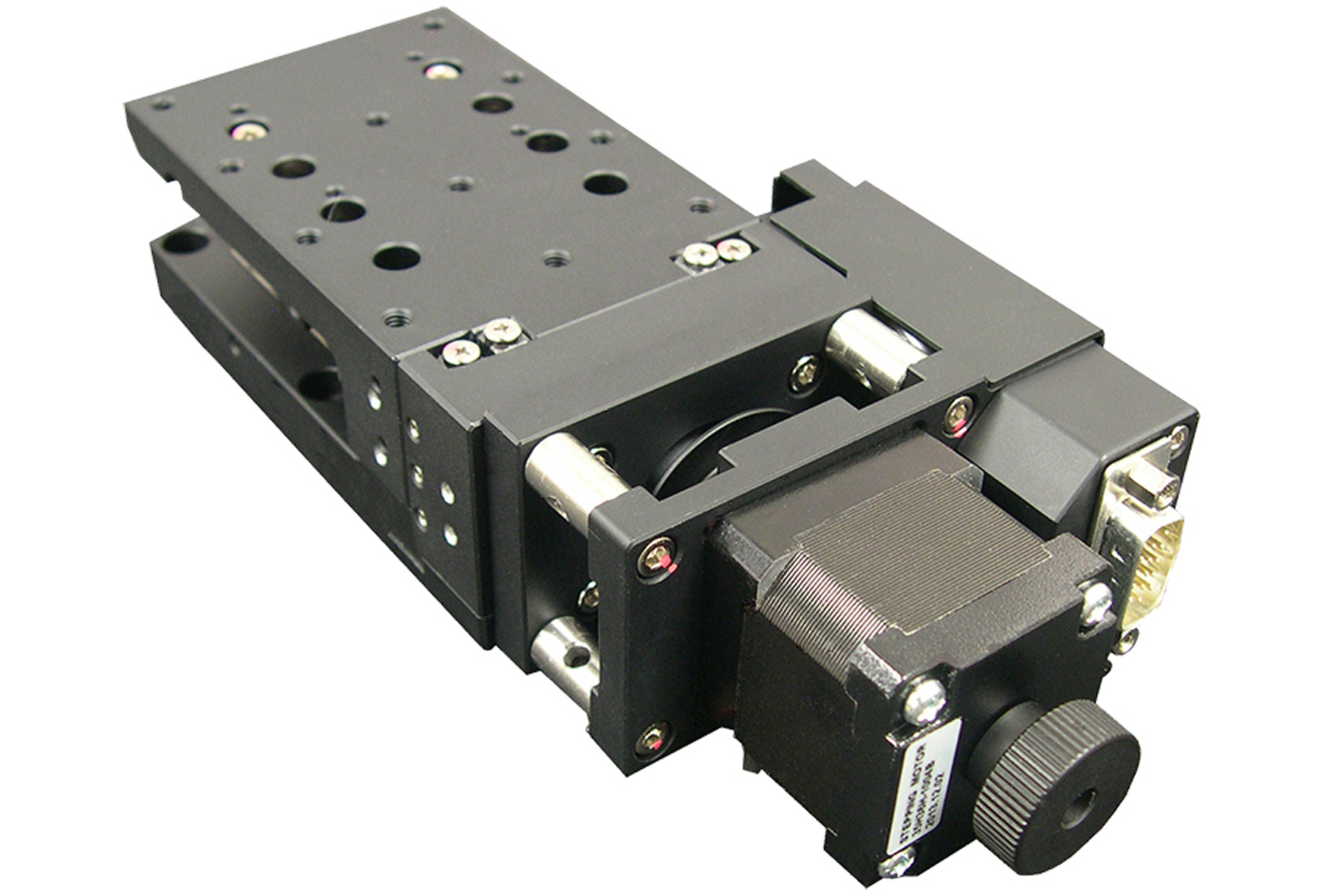

The AZ60-A Motorized Vertical Elevator Stage from Optimal Engineering Systems, Inc. (OES) is a low-profile and compact 183.7 mm x 80 mm x 38 to 42-mm (raised) stage.

It works for low cost, high resolution, wedge type, vertical elevator applications requiring precise vertical positioning.

The 60 mm x 95 mm (2.362 in. x 3.740 in.) drilled and tapped stage has a vertical travel of 4 mm (0. 157 in.). Six crossed roller guides and a precision ground 8-mm-diameter 250 µm/turn lead ball screw provides smooth, straight (straightness to better than 5 µm). More after the jump.

The stage delivers good parallelism (<20 µm to the mounting surface), and high resolutions to 1.25 µm (full step), 0.625 µm (1/2 step), and 0.125 µm (1/10 micro step), and repeatability to +/- 0.5 µm. Travel speeds are up to 2.5 mm/sec.

Applications for the AZ60-A elevator stage include:

• Photonic alignment, wafer inspection, precision vertical alignment, laser marking

• Optical positioning, testing, inspection, assembly, sampling

• Laser drilling and machining in a broad range of industrial, medical, semiconductor, and research facilities

The AZ60-A Elevator Stage is constructed of black-anodized aluminum alloy and weighs just 1.14 kg (2.51 lb). A powerful 35 mm NEMA 14 1.8° 2-phase stepper motor has a double ended shaft with a knob for manual adjustments. This knob may be replaced with a quadrature encoder for position verification. The non-cantilevered moving wedge elevator stage has a load capacity of 7 kg (15.43 lb) without concern for loss of parallelism, and the base plate has easy to access holes for mounting.

For more information, visit oesincorp.com.

Leave a Reply

You must be logged in to post a comment.