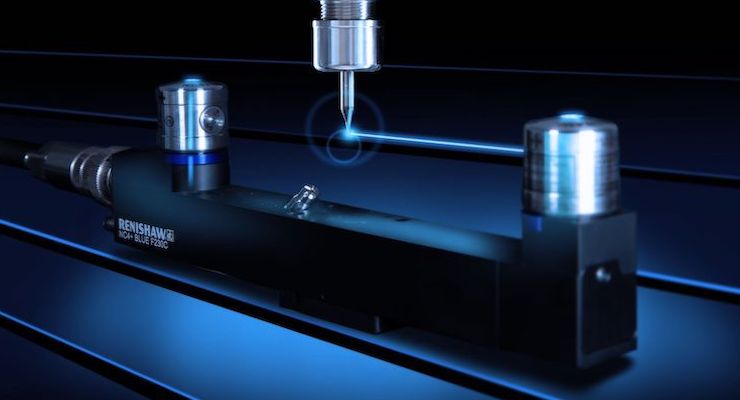

Building on the success of the original NC4+ Blue, the latest evolution of the non-contact tool setter features an ultra-compact design and is now available in four sizes, with operating gaps ranging from 55 to 240 mm. Measurement repeatability has also been improved across the range, now down to +/- 0.5 micron on smaller separations. Featuring blue laser technology and improved optics, Renishaw’s NC4+ Blue systems deliver significant improvements in tool measurement accuracy, ensuring components can be machined more accurately and efficiently.

Compared to red laser sources found in conventional non-contact tool setters, blue laser technology has a shorter wavelength resulting in optimized laser beam geometry. This enables the measurement of extremely small tools, while minimizing tool-to-tool measurement errors – a critical consideration when machining with a wide range of cutting tools.

NC4+ Blue systems use Renishaw’s non-contact tool setting software package, which continues to evolve to ensure rapid, robust and reliable measurement even in wet conditions. Auto-optimization technology within the software automatically adjusts the movement of the tool in and out of the beam to minimize any wasted movement and therefore cycle time. Features such as a dual measurement mode, where the tool is measured as it exits the laser beam, and an advanced tool cleaning option help ensure the tool is free from debris and coolant during measurement. Further enhancements to tool run-out and profile measurement cycles deliver increased functionality and reliability to advanced users.

The interior of a machining center is a hostile environment with coolant drips, swarf chips and dust commonplace. Coolant mist can saturate the air and quickly coat any exposed optical surfaces. Whatever their optical design, laser tool setting systems need clean optics and an unobstructed beam path in order to function. The NC4+ Blue uses MicroHole™ and PassiveSeal™ optical protection technologies, enabling fast and reliable tool measurement, even in wet conditions.

MicroHole technology ensures the optics are protected from contamination during measurement by delivering a continuous stream of compressed air through a very small and precise laser-drilled hole in the transmitter and receiver heads. The PassiveSeal system provides an additional layer of protection, automatically shielding the optics from contamination in the event of air supply failure. It uses a simple pneumatic installation that minimizes any need for maintenance.

NC4+ Blue support is now embedded into Renishaw’s extensive range of graphical user interfaces, including on-machine and mobile apps such as Renishaw Set and Inspect and GoProbe. These consistent, easy-to-use programming platforms are perfect for users who are new to probing or have little machine code knowledge, while still offering operational benefits to more experienced users.

Renishaw technologies provide the data that enables intelligent decision-making for Industry 4.0. On-machine tool measurement allows manufacturers to automate and optimize their processes and minimize quality problems and CNC machine stoppages. With the latest version of Renishaw’s on-machine Reporter app, users can now view historical tool data captured by the NC4+ Blue and stream the measurements in real-time. Results can also be exported via CSV file or PDF report and either stored for traceability or imported into in-house quality analysis software.

For more information, visit www.renishaw.com/nc4blue.

Leave a Reply

You must be logged in to post a comment.