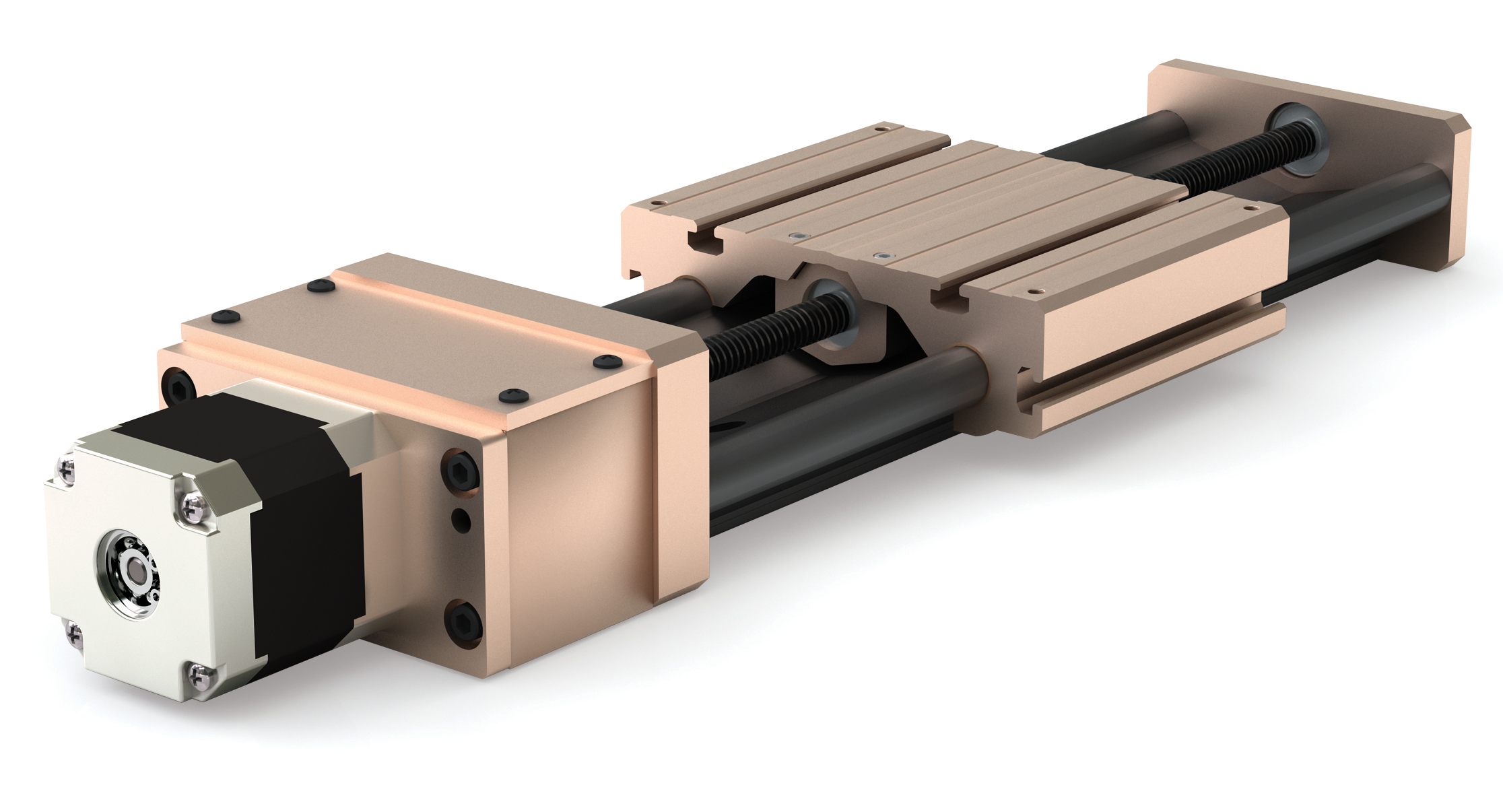

Updated May 2019 || When designing a linear motion system, engineers have two primary choices in recirculating linear guides — round shaft or profiled rail. Choosing the wrong linear motion system can be a costly mistake, resulting in design or structural changes, poor machine performance, or oversized components with higher costs. Although both round shafts and profiled rails may appear to be suitable options for most applications, there are typically a few criteria that dictate which technology is more appropriate.

Round shaft guides were invented in the 1940s and have been applied successfully in virtually every industry since their inception. But their limitations in rigidity forced manufacturers of precision equipment such as machine tools to use machined ways or cross rollers in order to achieve the required load capacities and accuracies.

The introduction of profiled rail guides in the 1970s offered a less costly and less time-consuming alternative … providing high load capacity and high rigidity in a fairly compact envelope.

But for designers, the decision regarding when to use round shafts became less clear, because profiled rail guides were suitable for many of the applications that had been the province of round shafts. As a result, decisions were, and sometimes still are, based on past successes (or failures) with a given technology. Fortunately, there are some key performance criteria that can guide the choice between round shafts and profiled rails and take the guesswork out of the initial selection.

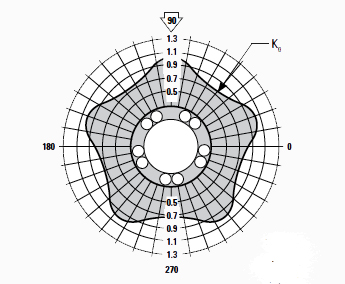

Load capacity

Advantage: Profiled Rail

With conformity between the balls and raceways, profiled rail systems have a larger contact area, and thus a higher load carrying capacity for a given size, than round shaft systems. Profiled rails are also better suited for moment loads than round shafts are, and typically have equal load capacities in all four directions. Conversely, the load capacity for round shafts depends on the direction of loading, which is the orientation of the load to the ball bushing.

Image credit: Thomson Industries

Linear guide rigidity

Advantage: Profiled Rail

The larger contact area between the balls and raceways yields less deflection for a profiled rail system than for a round shaft. And while round shaft guides can be lightly preloaded, profiled rail systems are often supplied with preload ranging from 2 to 8 percent, which provides further rigidity to the guide system.

Linear guide accuracy

Advantage: Profiled Rail

With ground raceways and reference edges, profiled rails commonly achieve travel accuracies that are an order of magnitude better than round shaft guides. In this criteria, round shafts are more commonly valued for their ability to handle inaccuracies (self-aligning) than for their travel accuracy.

Linear guide speed

Advantage: Profiled Rail

Round shaft guides can generally achieve a maximum speed of 2 m/sec, being limited by the ability to control the balls as they move in and out of the load zone. Profiled rail bearings, with a more sophisticated recirculation method, can reach speeds of 5 m/sec.

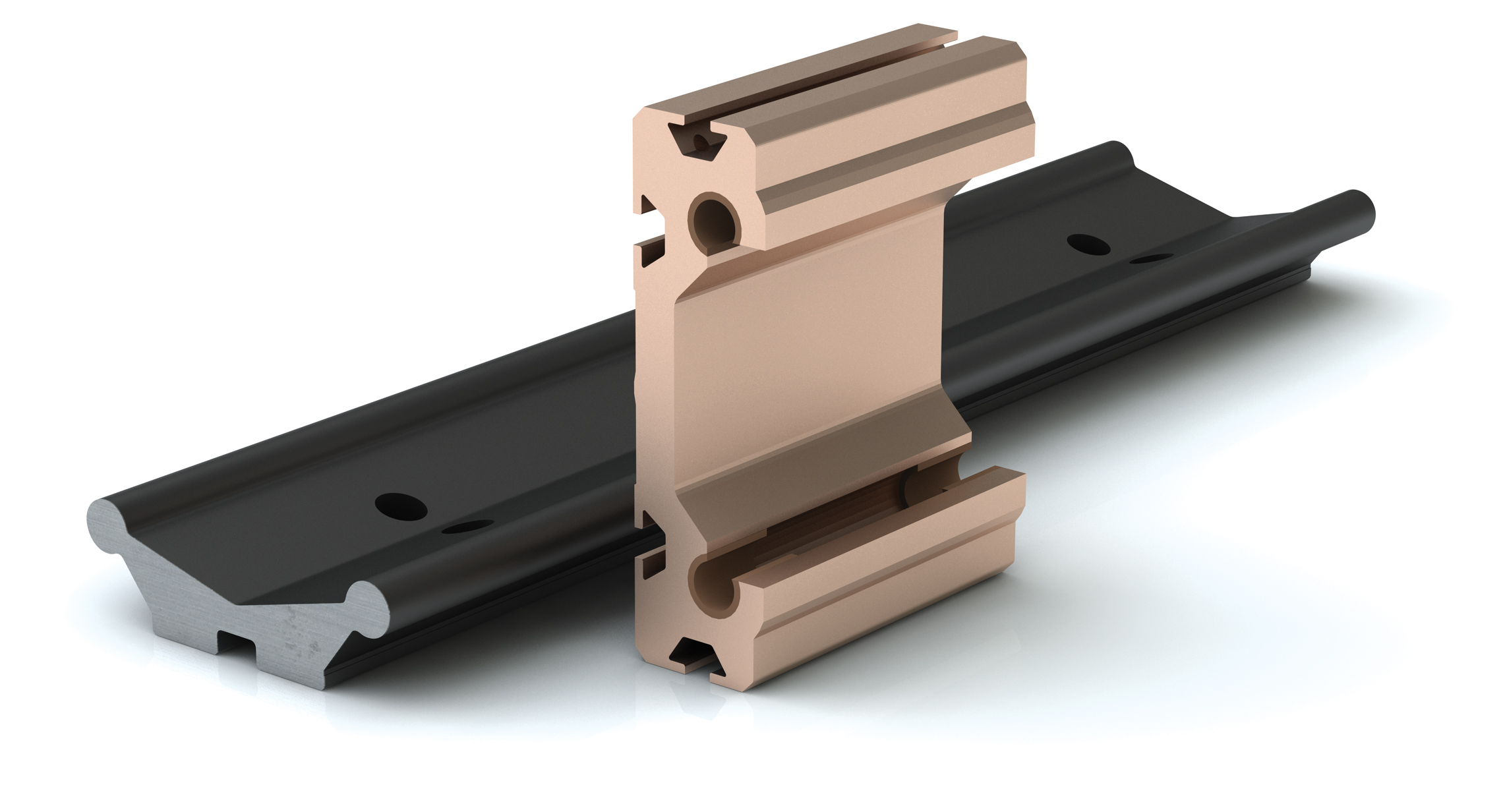

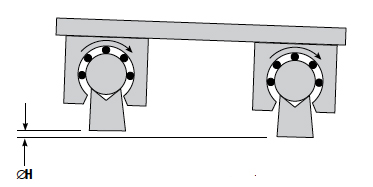

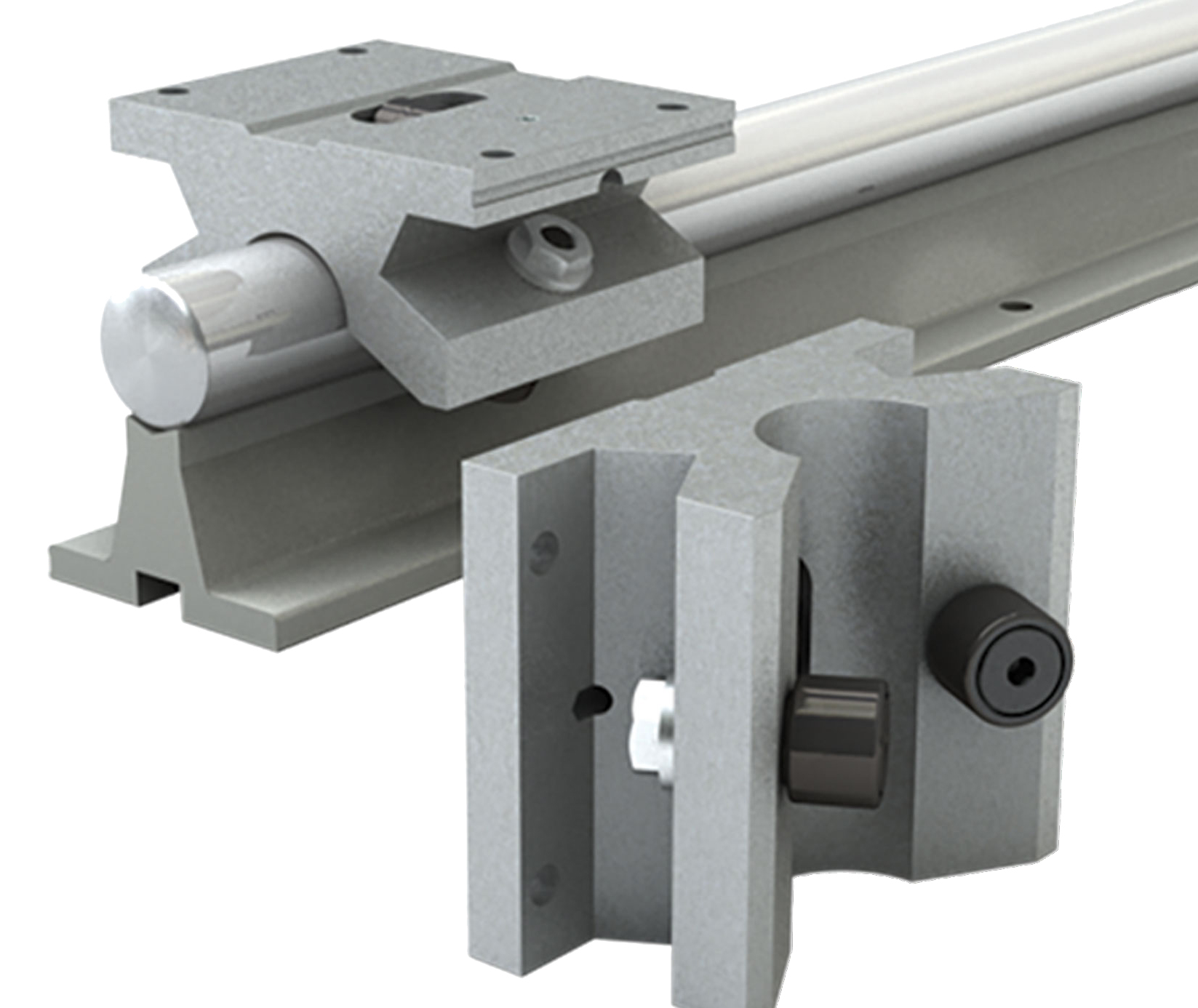

Linear guide mounting

Advantage: Round Shaft

Where profiled rail guides must be fully supported and mounted along their length, round shaft guides can be supported only on their ends, for lengths up to 20 times the shaft diameter. Round shafts also do not require machined surfaces for mounting, since ball bushings inherently compensate for some misalignment, reducing cost and time for designing and preparing mounting surfaces.

Image credit: Thomson Industries

Linear guide ruggedness in harsh environments

Advantage: Round Shaft

Round shafts are generally less sensitive to debris than profiled rails and are available in a variety of materials, coatings, and sealing options to withstand caustic or abrasive contamination. These range from all steel ball bushings to assemblies composed of stainless steel shafts with plastic bushings.

Linear guide maintenance requirements

Advantage: Round Shaft

Due to the smaller contact area between the load carrying balls and the running tracks, round shafts have less demanding lubrication requirements than profiled rails. Round shafts and ball bushings are also one of the few linear motion components that are, for the most part, interchangeable between manufacturers, which means that replacements are more readily available.

While profiled rails have the advantage in several of the traditional technical parameters—load, rigidity, accuracy—round shafts offer unique advantages that can ultimately lead to a lower total cost of ownership, in the form of easier integration, better suitability for challenging environments, and less maintenance.

Feature image credit: Thomson Industries

Thank you very much for the information provided!

Breaking the topic down in respective parameters and presenting which element has the advantage where as a basis for analysis was really wise, making the information easy to process…

You made everything very clear, therefore saving me a lot of research time, and for for that I am grateful!