The overwhelming majority of linear motion applications (with the exception of pneumatically-driven types) use either a stepper motor or a servo motor to provide torque to the driving mechanism, which is typically a ball or lead screw, rack and pinion, or belt and pulley system. And unlike other components involved in linear motion, when choosing a motor, there is usually a clear answer to the question, “Which technology should I use?” This is because servo motors and stepper motors are designed for very different performance characteristics. Determining which is to use for a given application requires understanding these differences and balancing them with other factors, such as cost and complexity.

Imaged credit: Advanced Micro Controls, Inc.

Positioning

The basic premise of a servo motor is that it operates in a closed loop system, meaning that an encoder or feedback device sends signals to the controller indicating the actual position of the motor. This information is compared against the commanded position, and the controller sends corrective signals to the motor in order to minimize the error. The result is very tight positioning accuracy and more reliable positioning than can be achieved with stepper motors. However, closed loop systems require tuning of the control parameters and are more time-consuming to set up. The additional components required for feedback and greater complexity also make them more expensive than steppers.

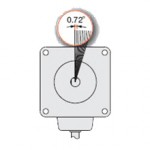

A stepper motor operates in an open loop system, with no feedback mechanism to confirm that the motor actually reached the commanded position. But achieving a precise position is generally easier for stepper motors because they move in discreet steps—with up to 500 steps per revolution, meaning that each step equals 0.75 degrees of motor rotation. When operated within their design limits, stepper motors don’t “lose” steps, giving them very good positioning accuracy for applications with predictable torque and speed requirements.

Speed

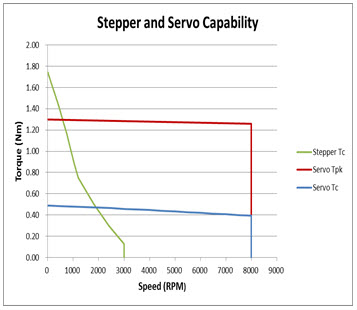

A general rule is that stepper motors are best suited for applications that run at 1000 rpm and below. This is because at higher speeds, a stepper motor’s torque production drops off rapidly. Servo motors can operate at a wide range of speeds, and they’re usually the better choice for high-speed applications.

At standstill, stepper motors can use their detent torque to hold a load in place, with no power to the motor. Servo motors are also able to hold a load at standstill, but require that the motor be powered in order to do so. Also, when at standstill, a servo motor is never completely still, since the controller constantly reads feedback from the encoder and issues move commands to compensate for any position errors. (This phenomena is sometimes referred to as “hunting” for position.)

Torque

As mentioned earlier, a stepper motor rapidly loses torque capability as its speed increases, with torque typically falling off at speeds above 1000 rpm. However, at lower speeds, steppers have excellent torque-producing capability for a given motor size. It’s important, however, to never exceed a stepper motor’s rated torque (which can limit its ability to accelerate), because doing so can result in lost steps or cause the motor to stall.

Servo motors are the better technology for applications where good torque production is required at high speeds. Servos are also able to maintain a given torque, even when the motor speed changes.

Image credit: Kollmorgen

In contrast to servo motors, which draw only the current needed to achieve the desired move, stepper motors draw current continuously, regardless of the load and speed. This results in higher heat generation, which may be a negative factor in some applications.

The verdict

In general, servo motors are the better choice for applications that require precise and accurate positioning, high speeds, and/or the ability to withstand changing loads (especially those that might require higher than the rated motor torque). For applications that don’t require position feedback and that operate solely within the design limits of the motor, stepper motors provide a simpler, more cost-effective solution.

This is one of the most common doubts when selecting electric motors. I’d like to share this content related with electric motors selection. You will find this and many other queries http://clr.es/en/home/download/free-ebook-electric-motors?ebook=electric_motors Hope you find it interesting.