Mechanical engineers are typically charged with designing, building, and applying a linear motion system for a specific machine or process. In doing so, our main concern is with attributes such as bearing life, deflection, and torque. And while we often work with the electrical and/or controls engineer for proper motor sizing and selection, rarely do most of us go beyond the basics of torque, speed, and inertia. But even if we never have to actually set up and tune a servo system, it’s helpful to understand the terminology and concepts that are key to servo performance.

Servo system hardware

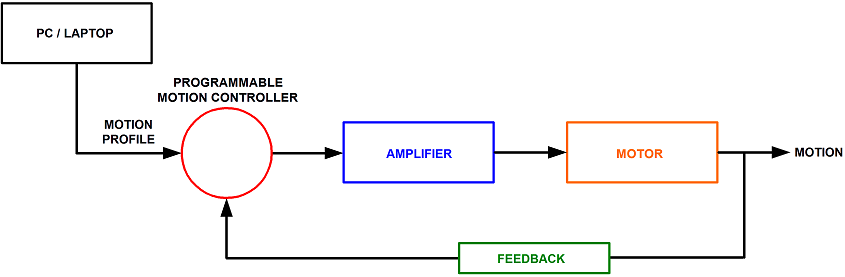

Servo motor: A motor that operates in a closed loop, using feedback from an encoder or resolver to compare the achieved position (or velocity or torque) to the commanded value and make corrective moves to eliminate the error.

Additional servo motor resources:

FAQ: What are the different ways that industry classifies servo motors?

FAQ: How are servo motors physically different from motors that run open loop?

Controller: The “brain” of a servo system. It determines the required move profile, outputs commands to the amplifier, takes feedback from the encoder or resolver, and issues corrective commands to compensate for errors. A controller can be a programmable logic controller (PLC) or a PC-based controller.

Additional controller resources:

Leading the trend toward integration in 2016: Motion controllers

3 Omron engineers answer 7 FAQs on controllers and PC-based motion control

Amplifier (aka servo drive): The “nervous system” of a servo system. The servo drive amplifies the signal from the controller to provide sufficient current to the motor in order to generate torque (for a rotary motor) or force (for a linear motor).

Additional amplifier resources:

Encoder: A device that measures the actual speed or position of the system being driven and sends this information as feedback to the controller.

Additional encoder resources:

FAQ: What types of linear encoders are there and how do I choose?

Linear encoders improve accuracy

FAQ: What’s the difference between single and multi-turn rotary encoders?

Servo control parameters

Feedback: Information provided by an encoder, resolver, or tachometer regarding the actual speed or position of the device being controlled.

Additional feedback resources:

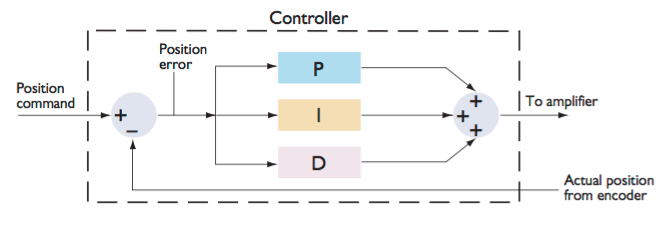

Tuning: A method of adjusting the gain and bandwidth values in the servo control so that the system’s achieved value (position, speed, or torque) matches the commanded (input) value as closely as possible.

Additional tuning resources:

Gain: The ratio of output to input; a measure of the amplification of the input signal.

Additional gain resources:

FAQ: What are servo feedback gains, overshoot limits, and position error limits?

PID: A type of control algorithm that uses three feedback gains—proportional gain, integral gain, and derivative gain—to control how hard the servo loop tries to correct or reduce the error between the commanded value (position, speed or torque) and the achieved value.

Additional PID resources:

Feed-forward: A control method that feeds gains into the control loop based on predicted (rather than past) error in order to improve system response.

Additional feed-forward resources:

Overshoot: The amount by which the actual value exceeds the commanded value.

Additional overshoot resources:

FAQ: What are servo feedback gains, overshoot limits, and position error limits?

Settling time: The time that a servo system takes to achieve and maintain a specified range (typically 2-5 %) around the commanded value.

Additional settling time resources:

Damping: A characteristic of how the system approaches the commanded value and its response to correction commands. A system may be over-damped (which can result in a slow response), under-damped (which can result in overshoot and oscillations) or critically damped (which minimizes settling time and oscillation).

Additional damping resources:

Leave a Reply

You must be logged in to post a comment.