SMAC now sells voice coil actuators that include differential features to satisfy OEM requirements … actuators that allow drop-in replacement of existing motion technologies having the same form, fit, and function. This design process is called MCA Inside and has been key in helping OEMs with an install base or an existing design to solve problems with minimal inconvenience in making an actuator change.

Parts are manufactured using precision plates with minimal machining required.

• Drilling, tapping, and reaming processes allow SMAC to offer actuators with the size and mounting arrangements of customers’ current solutions.

• Customer-specified housings: SMAC can install standard moving coil piston and magnet assemblies into existing housings.

SMAC’s latest cost reduction is primarily due to improved manufacturing efficiency.

Built-in controller options (around $200) offer internal programming and eliminate wiring with simple 24-Vdc/48-Vdc PLC I/O operation.

Benefits with SMAC MCA Inside:

• It’s possible to replace problem actuators (especially slow or inflexible or short-life motion solutions) with moving coil actuators

• Get an actuator that fits into a particular space on a new machine. This provides a suitable workaround the inflexible standard product offerings of many other actuator manufacturers.

• Get an actuator that meets special mechanical requirements for a given application — one that the design engineer knows about and others don’t.

Recent design wins for SMAC and its OEM customers and end users

SMAC actuators recently replaced a ball-screw stepper system with a bolt-in LBS17 (with cross rollers) to get more precision, longer life, and quieter motion.

SMAC actuators recently replaced a throwaway pneumatic air cylinder: The drop-in CBL actuator has a build-in controller to work an eject application … and eliminate downtime and delays for setup.

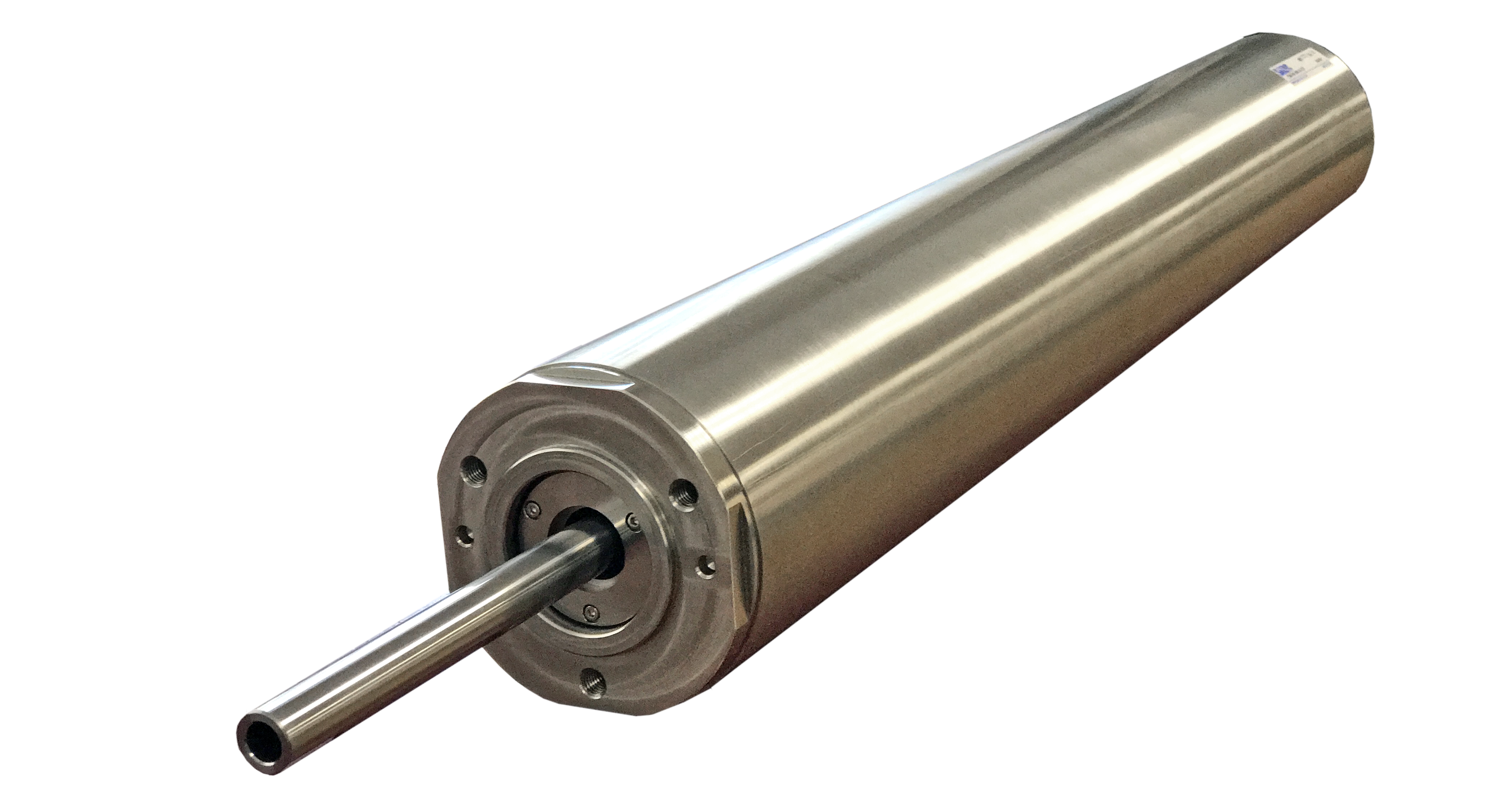

SMAC actuators recently replaced a moving-magnet linear motor with a rotary output. Now a SMAC CBR100 electric cylinder with Z-theta motion runs the axes in one unit on an OEM capping machine. This resulted in long life and capping to 100% specification.

SMAC moving coil actuators are true mechatronic solutions — with unique capabilities such as programmable and controllable position, velocity, and force, high accelerations, cycle life well over 100M, and a patent-pending Soft-Land capability. The Soft-Land capability is particularly useful when performing fragile part assembly, measurement, moving objects, and so on. Real-time feedback of these motion attributes provides proof the work is done to specification. For more information, visit www.smac-mca.com.

Leave a Reply

You must be logged in to post a comment.