High-precision linear guides are an important product group for NSK’s Linear Motion Technology (Seiki) management unit. As a specialist in this field, the company meets the requirements of many demanding market sectors, including the machine tool industry. Many of the linear guides supplied to European customers operating in high-precision, high-quality sectors are application-specific or adaptations of standard units.

Each plant in NSK’s global production network for linear motion products focuses on specific products. The company’s NH/NS series linear guides, for instance, is among the product ranges manufactured in Changwon, Korea.

Eduardo Rodriguez, Director Seiki Management Unit, European Industrial Business Unit, says: “The production of high-precision guides demands considerable know-how, which is contributed by our colleagues at the Changwon plant. This facility also uses proprietary NSK production machines, adding further to the extremely high performance and precision of our linear products.”

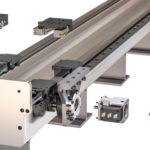

NH/NS linear guides offer twice the service life of conventional counterparts and up to 30% more dynamic load rating compared with previous generation models. Other benefits include long maintenance intervals, low noise and ease of installation. These advantages arrive thanks to innovative new design features, such as special ball raceway geometry, as well as the precision manufacturing of system components in Changwon.

Alongside high levels of innovation and quality, NSK always remains flexible in terms of customer requirements. Take the example of two recent customers in Europe: one producing medical devices and another manufacturing high-quality systems for textile printing. Both clients recently requested NH/NS series guide rails in specific lengths. Rail manufacturing in line with these demands took place in Changwon, before shipping to NSK’s plant in Newark, UK, for final packaging.

“Since the demand from both customers is continuous, we stock the customised rails in Newark so we can always deliver at short notice,” explains Eduardo Rodriguez.

Ultimately, the result is always the same: short lead times for bespoke linear guides. In addition, less effort is necessary for the processing of linear guides in Newark, which in turn lowers costs for customers and reduces environmental impact thanks to the elimination of waste and unnecessary operations.

This highly efficient and effective cooperation exists not only between NSK sites in Korea and the UK; the company’s international production network includes 64 manufacturing plants in 13 countries, all of which are highly specialized. Munderkingen, Germany, for example, is a highly flexible plant for the production of customized bearings used in mobile machines. Often manufactured in small batches, these bearings are popular among international manufacturers of agricultural machinery.

Leave a Reply

You must be logged in to post a comment.