Stepper motors are commonly used in linear motion applications for their precise positioning capabilities and good holding torque. And while the basic operating principle is the same for all stepper motors, there are differences in operation and performance between the three primary types: permanent magnet, variable reluctance, and hybrid.

Permanent magnet stepper motors

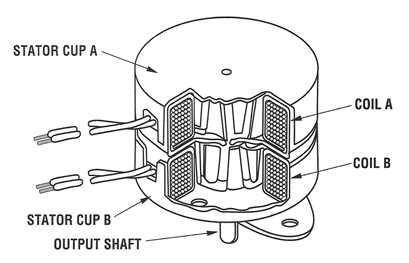

Permanent magnet types have a permanent magnet rotor that is axially magnetized, meaning it has alternating north and south poles parallel to the rotor shaft. These motors are also referred to as “can stack” or “tin can” motors because their stators consist of two coils contained in soft iron housings (i.e. “cans”) with teeth on the inside that interact with the rotor.

Permanent magnet steppers typically have a step angle of 3.6 degrees (100 steps per revolution), although models are available with 1.8 degree step angles. These motors can be operated in full-step, half-step, or microstepping modes for higher resolution. Permanent magnet stepper motors have higher torque capabilities than variable reluctance types (see below), but at limited speeds, so they’re best for applications that require low to moderate torque at low speeds.

Image credit: Applied Motion Products, Inc.

Variable reluctance stepper motors

Variable reluctance stepper motors have the simplest design of the three types, with a soft iron, non-magnetic, toothed rotor and a wound, electromagnetic stator. Because the rotor is not magnetized, there’s no attraction between the rotor and stator when the windings aren’t energized, so variable reluctance motors don’t produce detent torque.

Their dynamic torque production is relatively low, but they have less torque drop-off at higher motor speeds, so for mid- to high-speed applications, they are often a better choice than permanent magnet designs. Variable reluctance steppers are known, however, for their relatively high noise levels, so they’re not suitable for applications where noise is a concern.

Image credit: allaboutcircuits.com

Hybrid stepper motors

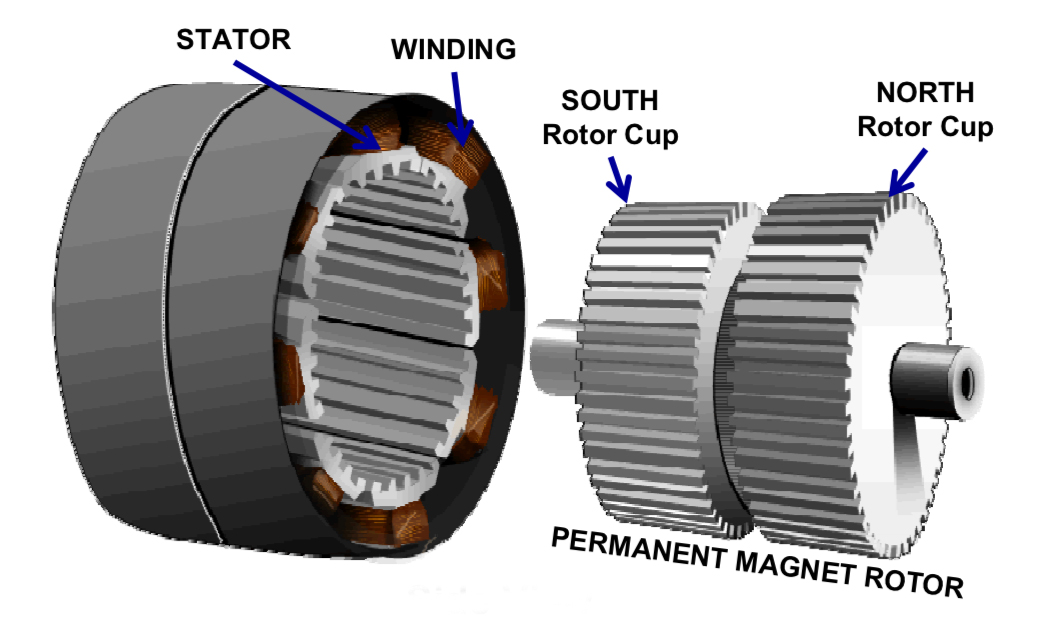

A combination of permanent magnet and variable reluctance designs, hybrid stepper motors have a permanent magnet, toothed rotor made from two sections, or “cups,” that are opposite in polarity and whose teeth are offset from each other. The electromagnetic stator is also toothed. The rotor teeth help guide the magnetic flux to preferred locations in the air gap, which improves their holding, dynamic, and detent torque when compared to permanent magnet and variable reluctance types.

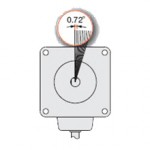

Hybrid stepper motors can also achieve higher resolution than other stepper motor types, with step angles as small as 0.72 degrees (500 steps per revolution) in full-step mode, with even higher resolution when half-stepping or microstepping is used. The hybrid design is arguably the most popular type of stepper motor, but a more complex construction makes it the highest-cost option of the three stepper motor types.

Image credit: Microchip Technology, Inc.

Great write up. I’d like to use very simple stepper motors in a hobby project. Specifically a 4/2 pole configuration variable reluctance stepper similar to what is described here. Any tips on where these can be purchased online?