Synchronous belts can transmit high torque without the potential for slip, due to positive engagement between the teeth of the belt and the grooves of the pulley. But the performance of synchronous belt drive systems can be affected by installation errors, unexpected application conditions, or the use of components that aren’t suitable for the operating requirements. Here are six ways that synchronous belts can fail and their most common causes.

Gates Corporation

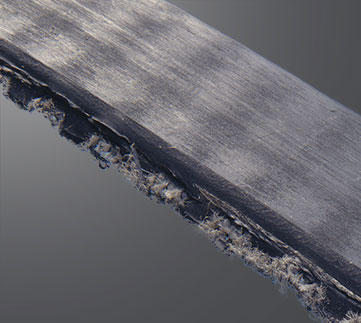

Edge wear

Flanged pulleys provide tracking for synchronous belts by resisting the lateral forces from the belt as it tries to move from side to side on the pulley. But in some cases, the belt can ride along the flange and exert significant force on it, resulting in wear on the edge of the belt. Common causes of edge wear are parallel misalignment, using a belt that is too wide for the selected pulley, or using pulleys that are damaged or have a rough surface finish.

Cracking

Belt cracking usually occurs parallel to the teeth, in the areas between the teeth (referred to as the “land areas”). Cracking is often associated with temperature issues – either a temperature that is too low at startup or too high during operation, causing the material to harden and crack due to bending. Other causes of belt cracking are a skewed pulley assembly or exposure to chemicals.

Gates Corporation

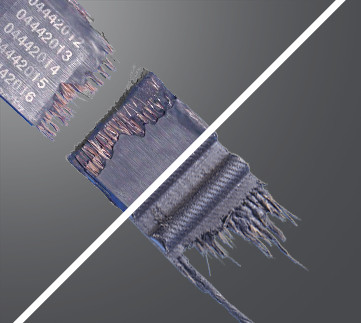

Tensile break

This type of failure is typically due to crimping or severe shock loads to the belt. Crimping often produces a tear straight across the belt and can be caused by mishandling of the belt, inadequate tension, a pulley diameter that is too small, or debris in drive system. Shock loads often result in an angled tear across the belt and can be accompanied by tooth shear.

Excessive tooth wear

Tooth wear is a normal result of the positive engagement between the belt and pulley and is mitigated by belt materials that are wear-resistant. However, excessive wear can result from either too much or too little tension, misalignment, excessive loading, debris in the drive system, a damaged pulley, or a pulley that is out of spec or does not have sufficient hardness. Under normal operating conditions, tooth wear generally does not affect the service life of the belt.

Gates Corporation

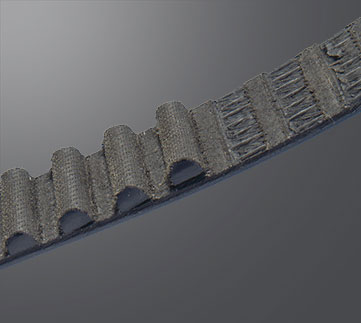

Tooth shear

Tooth shear is a catastrophic failure that can be caused by shock loads or misalignment. It can also be a result of insufficient tension, which causes a condition known as “self-tensioning” in which the teeth ride out of the pulley. When this happens, the load is no longer carried at the roots of the teeth, but rather further down the tooth flanks. This causes the teeth to bend and rotate, which can cause them to tear at their base and separate from the belt.

Ratcheting

Ratcheting is a condition in which belts jump or skip teeth on the pulley. The primary cause of ratcheting is insufficient belt tension. One of the benefits of synchronous belts, when compared to V-belts, is that once the tension is properly set, they do not require re-tensioning.

While synchronous belt failures can occur in many forms, pulleys generally fail in one of two ways: tooth wear or flange failure.

Abnormal or excessive pulley tooth wear is typically due to use in an abrasive environment, although pulley misalignment, excessive loading, and improper tension can also be causes. Pulley flange failure is most often a result of angular or parallel pulley misalignment.

can cause premature wear to belts and pulleys.

Image credit: Pfeifer Industries, LLC.

Great Insight! Thank you for sharing the causes of opting for the synchronous belt.

Very helpful!