Nook Industries, a leading innovator of linear motion components and systems, offers E-900 ball screw lubricant for use on any of its ball screw products, such as ball screw assemblies, ActionJac ball screw jacks and ball splines. The E-900 lubrication provides a lasting film for wear protection and corrosion resistance. The lubrication system offers a wide […]

Ball Screw

Standard ball screws now available from Nook Industries

Nook Industries, a leading innovator of linear motion components and systems, proudly offers a complete line of standard ball screw products. An upgrade from acme screws, ball screws provide advantages similar to those had by antifriction bearings over plain bushings. Ball screws serve a variety of applications, including machine tools, assembly devices and robots.Nook’s precision […]

How to avoid ball screw buckling

Imagine two columns—one short and wide and the other long and narrow. As you begin to put weight on them, the long, narrow column gradually begins to bend, to the point that it becomes permanently deformed and eventually breaks, while the short, wide column handles the weight with ease. In the same way the long, […]

How to determine if a screw will back drive

Screw assemblies are generally preferred over belts or linear motors in vertical applications. This is because a screw will prevent the load from catastrophically crashing if there’s a loss of power to the motor. But a vertical load can still cause a screw to back drive, allowing the load to drop, albeit at a slightly […]

What happens when you combine a planetary gear with a ball screw?

Answer: You get a planetary roller screw. Replacing the recirculating balls of a ball screw with grooved rollers results in a precision drive mechanism with extremely high load capacity, acceleration, and speed capabilities, all in a small footprint. Planetary roller screws fit well in applications at the upper end of ball screw capabilities, but that require […]

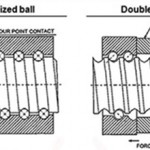

What is preload?

Have you ever wondered, “what is preload”? We’re here to help! Applications that use linear bearings or ball screws often require precise positioning, which means that the motion components must be rigid. And while recirculating ball guides and screws are able to carry large loads, they inherently have clearance, or backlash, due to the size […]

Inertia Matching: Why Perfect Isn’t Always Best

Inertia matching is one of the inexact sciences of motion system design. When a motor and a load are coupled together, the ratio of load inertia to motor inertia determines how well the motor can control the load during acceleration and deceleration. In theory, a “perfect” inertia match of 1:1 (load inertia equals motor inertia) should […]

Five Ways to Make Your Linear System Cleanroom Friendly

Implementing linear motion in a cleanroom presents a particularly difficult challenge, since motion – whether rolling or sliding – necessarily produces particles. But by understanding the sources that contribute to particle generation and implementing smart design options, it is possible to achieve linear motion without compromising even the most stringent cleanroom environments. Below are five ways […]

Linear Motion in the Third Industrial Revolution

According to The Economist magazine, a third revolution is coming for the manufacturing industry, ushered in by 3D printing, new materials, and collaborative manufacturing services. Anyone who has watched the 3D printing industry develop over the past decade, or even the past five years, will likely agree. Gartner forecasts that worldwide shipments of 3D printers […]

Linear Motor vs. Ball Screw

While ironless linear motors have been used in semiconductor and electronic applications for more than a decade, they are still viewed by many designers and OEMs as “niche” products. But the perception of linear motors as a costly solution for unique applications is slowly changing, as more industries are adopting them as replacements for ball screws […]