There are several reasons that a linear guide rail may be supplied in multiple sections rather than in one piece: the overall length is longer than the maximum offered by the manufacturer, the machine design or other space constraints don’t allow installation of a single piece in the length needed, or the risk of damage […]

calculation

How to calculate hole spacing for linear guide rails

Profiled linear guides—whether profiled rails, cam roller guides, shaft support rails, or plain bearing guides—are typically manufactured with evenly spaced mounting holes that allow them to be secured to a machine base or work surface. For rigidity and integrity of the rail, there’s often a minimum distance, specified by the manufacturer, that must be maintained […]

How to calculate combined static load

Static load capacity is an important factor in linear bearing selection. While dynamic load capacity is used to calculate bearing life, static load capacity indicates how much load the bearing can withstand before permanent damage occurs to the balls and/or the raceways. Even when they’re not moving, linear guides often experience a combination of both […]

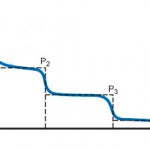

How to calculate mean equivalent dynamic load

It’s rare in linear motion for a guide or ball screw to carry the same load throughout its move cycle. Even in simple pick-and-place applications, the load will be higher in one direction (the pick and carry phase) than in the other direction (the place and return phase). But even more common is for a […]

Bearing load capacity explained

There are two load capacity specifications for recirculating linear guides and ball screws—static load capacity and dynamic load capacity. Most engineers are familiar with dynamic load capacity, since this is the value used to calculate bearing life. But it’s also important to consider the component’s static load capacity in order to avoid premature bearing failure. Here’s a […]

How to determine if a screw will back drive

Screw assemblies are generally preferred over belts or linear motors in vertical applications. This is because a screw will prevent the load from catastrophically crashing if there’s a loss of power to the motor. But a vertical load can still cause a screw to back drive, allowing the load to drop, albeit at a slightly […]

Three factors critical to servo motor sizing for linear motion systems

Selecting the right servo motor for a linear motion system is a complex task, beginning with initial assumptions and component selections, which must be checked through a series of calculations and, in most cases, repeated over several iterations until a suitable combination of motor and mechanics is found. Most motor manufacturers offer online sizing tools that make […]