With the range of technologies, designs, and options available for linear motion components, ploughing through the alternatives and making the best decision takes more time and resources than many designers and engineers are able to expend on any individual component. Looking back at the top 10 most-read Linear Motion Tips articles of 2015 confirms this situation. From primers on […]

Linear Drives

How to calculate ball screw rigidity

The rigidity of a ball screw determines the amount of elastic deformation it will experience in the axial direction, under a given load. Elastic deformation, and therefore rigidity, is a fundamental characteristic in selecting and sizing a ball screw, as it affects the positioning accuracy of the system. δ = Elastic deformation (μm) Fa = Applied force in […]

Bearing load capacity explained

There are two load capacity specifications for recirculating linear guides and ball screws—static load capacity and dynamic load capacity. Most engineers are familiar with dynamic load capacity, since this is the value used to calculate bearing life. But it’s also important to consider the component’s static load capacity in order to avoid premature bearing failure. Here’s a […]

Bearing lubricant: Choosing between grease and oil

Lack of bearing lubrication is generally regarded as the number one cause of linear-bearing failure. For recirculating linear bearings such as profiled rail guides and ball screws, lubrication separates the bearings (ball or roller) from the raceways, minimizes friction and wear, dissipates heat, and prevents corrosion. It also promotes smooth running of the seals and […]

The difference between inertia and momentum

The concepts of inertia and momentum are often confused — possibly due to the similarity of their definitions. Inertia is generally described as an object’s resistance to motion, with momentum being the tendency of an object to continue moving. Both have implications for linear motion applications, but while inertia is a fundamental sizing parameter, momentum […]

Linear motion tips for food and beverage applications

It’s not hard to understand why applications in the food and beverage industry are especially challenging for linear motion systems. Food processing and packaging equipment must simultaneously meet high throughput requirements and withstand harsh environments, while safely handling and processing products which are at constant risk for spoilage or dangerous contamination caused by environmental factors or improper handling. Add to this […]

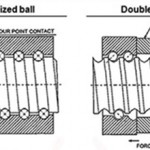

What is preload?

Have you ever wondered, “what is preload”? We’re here to help! Applications that use linear bearings or ball screws often require precise positioning, which means that the motion components must be rigid. And while recirculating ball guides and screws are able to carry large loads, they inherently have clearance, or backlash, due to the size […]

H2W Technologies Manufactures Brushless Linear Motors

With the recent acquisition of the Baldor linear motion product line, H2W Technologies has begun manufacturing brushless linear motors in its Santa Clarita, CA facility. With extensive experience in designing and building custom linear motion systems, and now, with the tooling necessary to produce both ironless and iron-core brushless linear motors, H2W has the capability […]

Inertia Matching: Why Perfect Isn’t Always Best

Inertia matching is one of the inexact sciences of motion system design. When a motor and a load are coupled together, the ratio of load inertia to motor inertia determines how well the motor can control the load during acceleration and deceleration. In theory, a “perfect” inertia match of 1:1 (load inertia equals motor inertia) should […]

Five Ways to Make Your Linear System Cleanroom Friendly

Implementing linear motion in a cleanroom presents a particularly difficult challenge, since motion – whether rolling or sliding – necessarily produces particles. But by understanding the sources that contribute to particle generation and implementing smart design options, it is possible to achieve linear motion without compromising even the most stringent cleanroom environments. Below are five ways […]