With so many linear guide choices—from roller rails to plastic wheels—deciding which technology is right for your application can be difficult. On one hand, not every application requires machine tool rigidity and the ability to move a small car. But on the other hand, most applications require a guide that can withstand high duty cycles […]

linear motion

Hardened way slides provide durability for long-life operations

Gilman Precision explains the basics of a hardened way slide, including which applications they are good for and how to keep yours in great working condition. Predominantly used for high production, hardened way slides provide linear rigidity for heavy duty applications. “A hardened way slide is a linear positioning device that incorporates precision, ground rectangular […]

When Do You Need a Gantry Robot?

When you think of an industrial robot, what comes to mind? Probably something like this… Articulated robots like these are widely recognized, thanks to car company commercials and robot dance sequences. SCARA (Selective Compliance Articulated Robot Arm) robots are also well-recognized due to their adoption and proliferation in factories since the early 1980’s. Both of these – articulated […]

What is preload?

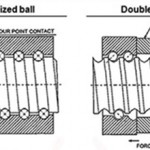

Have you ever wondered, “what is preload”? We’re here to help! Applications that use linear bearings or ball screws often require precise positioning, which means that the motion components must be rigid. And while recirculating ball guides and screws are able to carry large loads, they inherently have clearance, or backlash, due to the size […]

How to make your linear motion technology easy to maintain

Adding linear motion to articulated robots adds flexibility and extends the work envelope of your system. The 7th axis tracks that enable this linear motion all provide the same functionality but differ in one significant design feature: the antifriction bearing system used to support and guide the tracks. Watch this video to learn how to select the […]

High-class linear guides: How industry quantifies rail accuracy values

I once overheard a colleague, relatively new to linear motion and eager to be helpful, tell a customer, “H stands for our high-class rail.” While the thought of a “high-class” rail was amusing, technically she was correct. In profiled linear guide terminology, H is the designation for high class … … high accuracy class, that […]

Can Lead Screws Outperform Ball Screws?

Lead screws are often regarded as the less expensive alternative to ball screws – suitable only for light-duty applications with low precision requirements. While it’s true that ball screws often have the advantage over lead screws when it comes to load capacity and rigidity, lead screws’ reliance on sliding, rather than rolling, motion makes them the better choice for […]

Inertia Matching: Why Perfect Isn’t Always Best

Inertia matching is one of the inexact sciences of motion system design. When a motor and a load are coupled together, the ratio of load inertia to motor inertia determines how well the motor can control the load during acceleration and deceleration. In theory, a “perfect” inertia match of 1:1 (load inertia equals motor inertia) should […]

Five Ways to Make Your Linear System Cleanroom Friendly

Implementing linear motion in a cleanroom presents a particularly difficult challenge, since motion – whether rolling or sliding – necessarily produces particles. But by understanding the sources that contribute to particle generation and implementing smart design options, it is possible to achieve linear motion without compromising even the most stringent cleanroom environments. Below are five ways […]

Linear Motion in the Third Industrial Revolution

According to The Economist magazine, a third revolution is coming for the manufacturing industry, ushered in by 3D printing, new materials, and collaborative manufacturing services. Anyone who has watched the 3D printing industry develop over the past decade, or even the past five years, will likely agree. Gartner forecasts that worldwide shipments of 3D printers […]