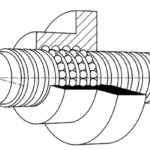

THK’s new Type SDA-V/SDAN-V caged ball screw is engineered to enable the development of high-speed machine designs. Featuring newly developed circulation components, the Type SDA-V/SDAN-V picks up balls in the tangential direction and achieves a maximum rotational speed of 5,000 rpm — for a maximum DN value of 160,000. Torque remains stable even during long periods of high-speed operation. Type SDA-V/SDAN-V nut dimensions conform to DIN standards (DIN69051-5).

The Type SDA-V caged ball screw is suitable for a wide range of applications — from small electronic component machinery to large general industrial equipment. 59 products are available with a combination of shaft diameters from ø12 to ø50 and leads from 4 mm to 50 mm. Clearance can be selected … including an axial clearance of 0 or less.

In contrast, the Type SDAN-V caged ball screw is designed with higher axial rigidity than the Type SDA-V. It is suitable for use with NC machine tools and precision equipment when is it necessary to minimize displacement from the force of cutting. Shaft diameters range from ø31 to ø50 and leads from 10 mm to 20 mm. A double nut allows axial clearance of 0 or less.

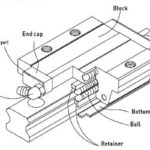

Full-ball versions are available for both the Type SDA-V and the Type SDAN-V. The Type SDA-V/SDAN-V features patented THK Caged Technology for smooth and quiet motion. Caged Technology employs a synthetic resin cage with a patented curvature that cradles each ball and separates it from the next. The spaces between the rolling elements retain grease and act as a lubrication system for long-term maintenance-free operation. Other Caged Technology benefits include increased speed and accuracy, decreased noise levels, low dust generation and long life.

The Type SDA-V/SDAN-V complies with conventional JIS (Japanese Industrial Standards) as well as ISO (international standards) and DIN (German industry standards).

THK manufactures the widest range of linear motion products, including LM guides, ball screws, mechanical actuators and ball splines and more. All THK products have been designed and manufactured to meet the strictest requirements. THK’s experienced Global Engineering Team can provide customized linear motion solutions from their standard linear motion products as well as from mechatronics products for the most demanding applications. For more information, visit www.thk.com.

Leave a Reply

You must be logged in to post a comment.