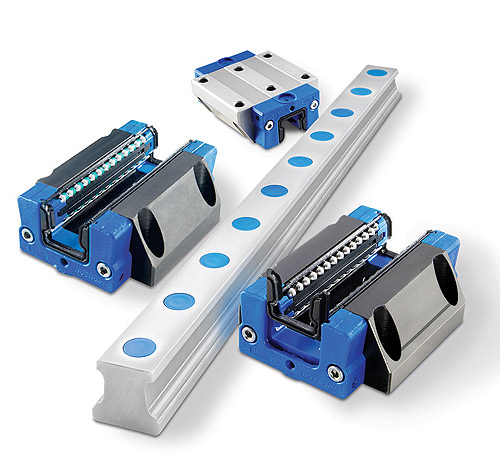

WOOD DALE, IL – Thomson announces that high performance Thomson 500 Series Profile Rails now come standard with an enhanced carriage design that delivers 66% smoother operation with up to 50% lower drag force than previous models. Additionally, a ball spacer carriage option is available to reduce carriage running noise by up to 6 dB. Enhanced design models are 100% interchangeable with previous Thomson 500 Series carriages and rails.

The new design optimizes the surface interfaces between steel and plastic transition areas along the ball bearing circulation path for more precise operation. New standard end seals provide twice the contaminant protection compared to competitive products, with optional low drag end seals idea for low push-force requirements. Additionally, new optional 440B stainless carriages and rails deliver corrosion resistant operation ideal for applications such as medical, electronic assembly, semiconductor, and food and beverage applications.

“Thomson 500 Series Profile Rails have four longitudinal seals per carriage to provide much better contaminant protection than competitive designs that typically have just two longitudinal seals,” says Tom Dwyer, Business Unit Manager, Thomson Profile Rail Bearings. “An additional lubrication reservoir enables longer running time between servicing, while easy-change end caps and seals can be replaced in seconds to help maximize machine uptime.”

The optional noise-reducing ball spacer carriage is available for size 20, 25, 30, 35 and 45 500 Series Profile Rails. The significant noise reduction is achieved by inserting plastic discs between each ball bearing, preventing the balls from contacting each other or bumping into the ball track. All external carriage dimensions are exactly the same, making it a simple drop-in replacement for current ball carriages.

Thomson

www.thomsonlinear.com

Leave a Reply

You must be logged in to post a comment.