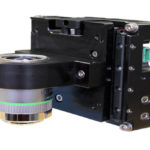

The new AU300-AER three-axis gimbal mount from OES (Optimal Engineering Systems, Inc.) features full 360˚ rotation of each axis. This three-axis gimbal mount handles loads to 10 kg (22.5 lb) and has a clearance of 300 x 300 mm, (11.8 in. x 11.8 in.) around the roll axis stage. The azimuth stage rotary table is mounted on a large 360 x 360 x 13 mm (14.173 x 14.173 in. x 0.512 in.) plate with handles and has predrilled accessible mounting holes for easy integration into new or existing applications, and for increased stability. The AU300-AER three-axis gimbal mount is ideal for mounting cameras, optics, lasers and instrumentation for scanning, tracking, positioning, pointing, and other applications.

The three axes (azimuth, elevation, and roll) are driven by bi-directional stepper motors capable of microstepping, and have knobs for manual adjustments. The roll axis table measures 100 mm (3.937 in.) in diameter. The knobs may be replaced with optical encoders for position verification and closed loop positioning. Each axis features low backlash worm gear drives and precision “V” groove and cross roller bearings for high resolution of 3.6 arc seconds, and repeatability and positional accuracy to 36 arc seconds. Travel speed of each axis is 8˚ per second. Electrical connections are made using three 9-pin DB-9 connectors.

The AU300-AER Motorized Three-axis gimbal mount can be ordered as a complete plug-and-play system with a multi-axis controller, joy stick, track ball, or keypad, and with a 30-mm thru hole in the roll stage.

For more information, visit www.oesincorp.com.

Leave a Reply

You must be logged in to post a comment.