From a design standpoint, the most important criteria when selecting a ball screw assembly is the method used for recirculating the load-carrying balls of the ball nut. The ball nut recirculation method is a determining factor for the smoothness of motion and size of the ball screw assembly. It also has a significant influence of the screw’s maximum speed, or DN value, based on the return mechanism’s design and ability to handle the forces that arise when changing the speed and direction of balls.

There are three primary ball nut recirculation approaches—one that manages the recirculation outside of the ball nut housing and two that achieve recirculation within the nut housing. While no approach is universally superior to the others, each one has features that make it more suitable to particular applications or design requirements.

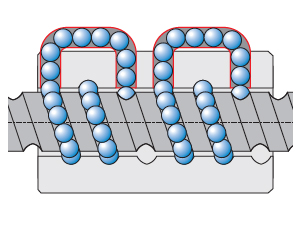

External Recirculation

External ball return involves one or multiple tubes which are located outside the diameter of the ball nut. Pickup fingers guide the balls into the tube(s) to be circulated back to the starting point. When one return tube is used, it spans all the ball tracks, from one end of the ball nut to the other. The more common design, however, uses multiple tubes, each of which spans 1.5 to 3.5 ball tracks.

The external return tube design is easy to assemble, making it well suited to mass production and generally a lower-cost option than other recirculation methods. It is also suitable for a wide range of shaft diameters and leads. However, the physical size of a ball nut with external return tubes tends to be large, so the available space and mounting options within the assembly should be carefully considered when using a ball nut of this design.

Image credit: Bosch Rexroth. Used with permission.

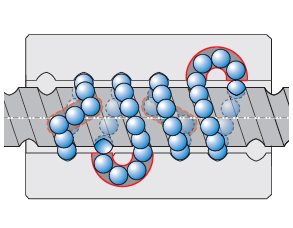

Internal Recirculation

When the balls remain contained within the nut housing during recirculation, this is considered internal ball recirculation. There are two primary methods to achieve internal recirculation—using deflectors or using end caps.

With recirculation via deflectors, balls are lifted across the diameter of the ball screw and guided to the adjacent ball track. This design features one deflector per ball circuit, which makes it especially suitable for ball screw assemblies with small leads. It also yields a very compact ball nut for applications where space is a primary consideration.

Image credit: Bosch Rexroth. Used with permission.

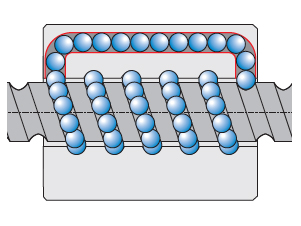

For high lead ball screw assemblies, which typically run at higher speeds, end caps are the best option for ball recirculation, due to the forces produced by the fast-moving balls. In this method, the ball nut features a bore along its length, with end caps on each end of the ball nut. The end caps pick up the balls from the raceway on one end of the nut and guide them back into the raceway on the opposite end.

In addition to allowing high speed operation, end cap recirculation produces a quiet ball screw assembly, since the recirculation channel is located within the nut body. However, this recirculation design is less suited to mass production and can be more expensive than external recirculation designs.

Image credit: Bosch Rexroth. Used with permission.

Most manufacturers offer a range of ball nuts that spans all three recirculation methods, depending on the nut style, diameter, and lead. In addition to the common sizing parameters (load, speed, thrust), space and mounting considerations will help determine which ball nut recirculation method is best for a given application.

Feature image credit: Bosch Rexroth

Leave a Reply

You must be logged in to post a comment.