Linear motors are often thought of as either flat or U-channel designs. But tubular, or shaft-type, linear motors have a construction principle that provides higher efficiency and makes them especially well-suited for gantry applications.

Benefits of cylindrical design

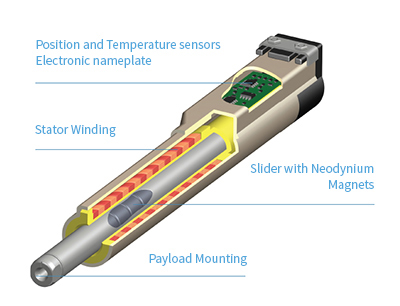

Tubular linear motors consist of a thrust rod (or tube) with permanent magnets and a stator (sometimes referred to as a forcer) with coils. The most common configuration is a fixed thrust rod with a moving stator, to which the load or tooling can be attached. But some manufacturers offer configurations in which the rod extends and retracts from a housing that encloses the stator. This design provides an alternative to pneumatic or screw-driven rod-type actuators. In rod-style thrust applications, linear motors provide high speed and acceleration, the ability to withstand high duty cycles, and precise positioning.

Image credit: LinMot USA, Inc.

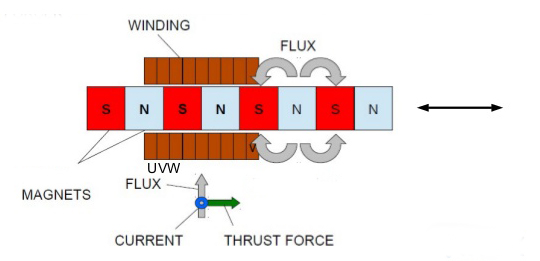

The primary benefit of tubular linear motors over flat and U-channel types is their high efficiency. Linear motors work on the principle of the Lorentz Force, which states that when a conductor with current (the stator) is placed in a magnetic field that is perpendicular to the current, a force is generated on the conductor. The direction of the force is perpendicular to both the magnetic field and the current. The key for tubular linear motors is that their design allows the entire coil (not just a portion of the coil, as in flat and U-channel designs) to be perpendicular to the magnetic flux, so all of the current is used to generate force in the direction of travel, maximizing their efficiency.

Image credit: Nitek

High efficiency devices generate less heat, so less cooling is needed. Less heat also means less expansion and contraction of components due to thermal effects, and more importantly, less heat transferred to the external load or work environment. The result is better positioning accuracy, which is especially important for cutting, machining, or dispensing applications. Although some designs are available with iron core stators for higher force production, most tubular motors are ironless, so they have no cogging effects and produce very smooth motion.

The air gap, or space between the thrust rod and the stator, is relatively large, at 0.5 mm to 2 mm, and the round design balances the attractive forces between the rod and stator. Together, these features make installation and assembly of tubular linear motors easier than for other linear motor types.

Gantry systems

As with other linear motor types, tubular motors are often integrated with a linear bearing system to provide not only drive force, but also guidance for a load. Their round design makes them ideal for integration with a single guide rail. In gantry systems (with two actuators on an axis), single-rail actuators are preferred over dual-rail designs because systems with more than two rails operating in parallel are much more likely to experience misalignment between rails, which causes binding and premature wear. In fact, many linear motor gantries use tubular style linear motors. And like other linear motors, tubular designs can drive more than one stator on a single thrust rod for multiple, independent movements on the same axis.

Image credit: Ibex Engineering, Inc.

LinMot has put together a video collage of applications using tubular linear motors that you can watch here. If you’re pressed for time to watch the entire video, check out the parallel kinematics application at approximately 0:43 and the coordinated motion (hexapod) application at approximately 1:13.

Feature image credit: Nippon Pulse

Leave a Reply

You must be logged in to post a comment.