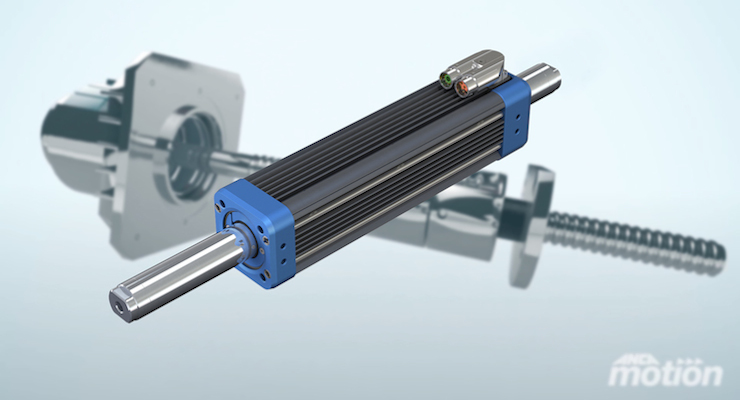

Like other tubular linear motors, ANCA Motion’s LinX M-Series is designed to be close in form to ball screw systems, offering easy substitution for those who want to make the change.

Both cylindrical linear motors and flatbed linear motors have superior accuracy and repeatability compared to ball-screw options. A tubular linear motor is also a much simpler design, with only two moving parts (the shaft and forcer) and does not have to rely on intermediate components such as a gearbox to change torque.

Ball screw actuators are also sensitive to jerk, and lack the nimbleness of tubular linear motors. The contact between the nut and screw means lubrication is essential, and causes wear and performance degradation over time.

“When you install a ballscrew motor into a machine, the tolerance that you need to achieve for a stroke will be much more stringent than for a tubular linear motor,” explains Heng Luo, product manager at ANCA Motion. “M-Series has a big advantage here, because of the 1-mm air gap between the shaft and the forcer, which keeps a relaxed tolerance requirement.”

Besides being wear-free due to the 1-mm air gap between forcer and shaft, the M-Series offers peak resolution of 10 µm, peak velocity of 10 m/sec, and maximum acceleration of 30 N.

It also overcomes the issue of backlash suffered by ball screw actuators. “In ballscrew systems, motion is created by direct contact between the surface of the nut and the lead,” explains Heng Luo. “There will be some gap between the nut and the lead, otherwise the nut won’t move. So there has to be a gap, and there has to be backlash, and this can be corrected to some degree but never removed completely.”

The direct contact also means noise and dust are created. Switching to tubular linear motors and avoiding this is an advantage for cleanroom use.

With no backlash, no wear, a high level of dynamism and low level of maintenance, the M-Series represents immediate gains in manufacturing productivity. The M-Series also has a failure rate under 0.03 percent.

ANCA Motion’s linear motors were originally developed for sister company ANCA Machine Tools’ FX Linear and MX Linear machines. ANCA is a leader in CNC tool grinding technology, with a series of world firsts since beginning in 1974. M-Series have been developed within a culture of world-class engineering, developing machine tools where micron-level precision is treasured. An international network of 125 engineers in strategic locations is on hand, offering fast, reliable support.

For more information, visit https://motion.anca.com.

Leave a Reply

You must be logged in to post a comment.