Vention, the first digital manufacturing platform dedicated to machine design, and Thomson Industries, a global leader in mechanical motion technology, are announcing their partnership for linear motion components compatible with the Vention hardware and software platform.

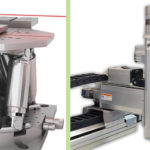

The Vention platform allows for the design, order and commissioning of factory equipment in just days. Premium custom linear axes can now be added to any design created in Vention’s MachineBuilder. Thomson’s shafts and linear bearings will enable a new range of high-duty cycle applications such as 7th axes, palletizers, cartesian robots and more. The integration of Thomson components in Vention’s digital workflow enables unparalleled speed and simplicity when creating linear motion systems.

Benefits for customers include:

- Accelerated design and delivery of premium linear axes

- Real-time pricing of full solution while designing in the MachineBuilder

- Available for timing belt- and ball screw-driven applications

- Four lengths available for next-day delivery (585 mm, 855 mm, 1530 mm, 2295 mm)

“The integration of Thomson components in Vention’s platform will greatly expand the range of automated equipment that can be designed, ordered and commissioned at unparalleled speed,” said Patrick Halde, VP of Business Development at Vention.

Kyle Thompson, Thomson Product Innovation Manager, said, “We know that engineers are busier than ever. They need to design and build quickly so they can move on to their next project. Vention offers a unique platform that enables both of these aspects and drastically reduces the overall design cycle. We’re excited for Thomson to be part of the Vention library and to expand the portfolio of potential machine applications within the platform.”

Leave a Reply

You must be logged in to post a comment.