Recirculating linear guides get significant media attention, thanks to their versatility and wide range of uses. But linear guides based on sliding contact — namely boxway and dovetail slides — are often the bearings of choice for applications that call for high load capacity, extreme stiffness, and excellent vibration damping characteristics.

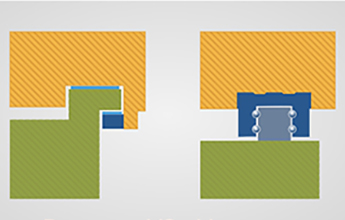

Boxway slides are a type of plain linear bearing, with a somewhat “T-shaped” base and a mating saddle, or carriage, that fits around the profile of the “T.” This geometry gives boxway designs a large area of contact between the base (stationary part) and the saddle (moving part), which results in extremely high load capacities. In fact, boxway slides typically have the highest load capacities and highest stiffness of any linear guide system — rolling or sliding. The downside of this sliding contact is increased friction, which lowers the permissible speed, although speed isn’t typically an issue for the heavy-duty machining applications where boxways are most often used.

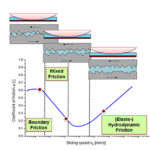

The base and saddle of a boxway slide can both be made from cast iron, or the base can be made from cast iron and the saddle from steel. The ways — the surfaces on the underside of the saddle that actually ride on the base — are typically coated with a friction-reducing material such as Turcite or Rulon, both of which are reinforced PTFE-based materials. These non-metallic coatings offer superior protection against the effects of stick-slip and corrosion and, together with the shear mass of the boxway assembly, contribute to the slide’s vibration-damping capabilities.

Because of their large contact area, boxways require very precise manufacturing tolerances. The saddle and base are precision-ground (top and bottom) to ensure parallelism and flatness of travel. And most boxway slides have hand-scraped ways that improve accuracy, reduce friction, and create pockets for lubrication, which is typically provided via a pressurized oil-delivery system.

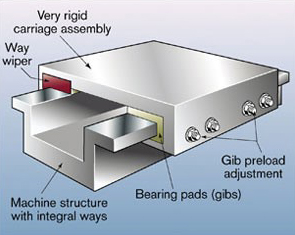

One or more adjustable plates, referred to as “gibs” or “gib plates” are used in boxway slides to remove clearance between the base and the saddle and create preload, which is typically required for machine tool applications to improve rigidity and accuracy.

Image credit: Devitt Machinery Company

Scraping is the process of creating high and low spots on mating bearing surfaces. The high spots created by scraping ensure even distribution of the load and prevent one surface from “rocking” on the other. The combination of high and low spots creates pockets that hold oil, ensuring proper lubrication between the surfaces — especially during startup.

Scraping is almost exclusively done by hand (known as “hand-scraping“) by highly skilled technicians who analyze the interferences between surfaces and determine where scraping is needed. In boxway manufacturing, the goal of hand scraping is typically to create 10 to 15 contact points per square inch.

In addition to higher load capacity and better rigidity, boxway slides can also provide significant damping for machine vibrations — something that recirculating linear guides, with only point or line contact, cannot provide. Vibration damping not only improves the surface finish and accuracy of the machining process, it can also increase tool life by reducing small but destructive vibrations in the tool.

While recirculating profiled rail bearings and dovetail slides are used in many machine tool applications, boxways are the primary choice for machine tools designed for high-horsepower, “hard” cuts and for materials that are especially difficult to machine, such as aerospace alloys.

Feature image credit: Gilman Precision

Leave a Reply

You must be logged in to post a comment.