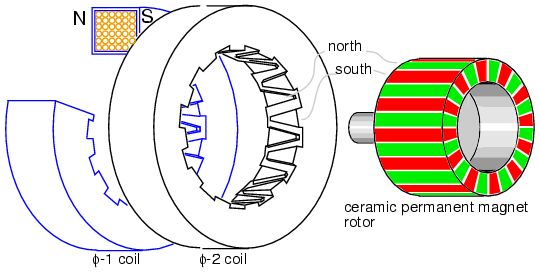

Can stack linear actuators are based on can stack stepper motors, which are a form of permanent magnet steppers that consist of two stators (and therefore two coils) stacked on top of each other. The poles of each stator are “claw tooth” design and are offset from each other by one-half of the pole pitch. The rotor consists of a permanent magnet, and it has the same number of pole pairs that each coil has.

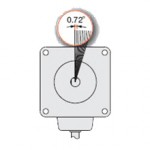

The stacked design of the two stators, or cans, means there are four discrete positions that can be induced for each pole pitch. A common design for can stack actuators has 24 poles in each coil, or phase. With 24 poles around a 360 degree cylinder, the pitch between poles on a single stator is 15 degrees. But since the two stators are offset by ½ pole pitch, there are 7.5 degrees (½ of 15) between the poles on each stator. This means when the stators are energized individually, the motor will rotate 7.5 degrees for each step, or energizing pulse. The sequence in which the phases are energized determines the direction of rotation, and the frequency of pulses determines the speed of rotation.

Image credit: allaboutcircuits.com

In order to make a linear actuator out of a can stack stepper motor, the rotor is threaded, and a screw (typically a lead screw) is integrated into the rotor, so that it extends and retracts as the motor turns. There are three common designs for can stack linear actuators. When the screw is captured by a device – either internal or external to the motor – that prevents its rotation, the actuator is referred to as a captive linear actuator. But manufacturers also offer non-captive actuators, in which the screw will rotate along with the motor. When a non-captive design is used, rotation is typically prevented by the design of the application. In the third can stack actuator design, the screw does not extend and retract. Instead, the nut is external to the motor and travels along the screw as the motor and screw turn together.

Image credit: DINGS’ MOTION USA

Like other stepper motors, can stack linear actuators are commonly operated in open-loop mode. Although stepper motors do have step error (± 0.5 degrees, for example), the error doesn’t accumulate over multiple steps, which allows good positioning accuracy. And many designs can be operated in full-, half-, or micro-stepping modes. Can stack linear actuators also take advantage of the detent torque of the stepper motor to hold position, even when there’s no power supplied to the motor.

Industrial applications for can stack linear actuators include medical diagnostic equipment and pumps. But suitable applications for these small, precise linear actuators range from consumer devices such as printers and copiers to military applications for radar and antenna positioning.

Feature image credit: Portescap

Leave a Reply

You must be logged in to post a comment.