Piezo materials are a special type of ceramic that expands or contracts when an electrical charge is applied, generating motion and force. (Conversely, piezo materials will also generate energy when a mechanical stress is applied.) Piezo actuators harness this motion to provide very short strokes with high frequency and fast response times. They also generate high forces relative to their small size, giving them a significant power-to-size ratio.

Because of their conversion of electrical energy to mechanical energy, piezo devices are often referred to as motors, but the term “actuators” is used interchangeably.

The piezoelectric effect produces motion that is parallel to the electrical field. Some actuators, however, operate on the transverse piezoelectric effect, in which motion occurs orthogonally to the electrical field. There are four main types of piezo actuators, distinguished by the arrangement of their piezo elements and by the type of movement they generate.

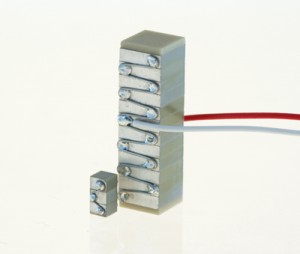

Longitudinal actuators

Also called piezo stacks, longitudinal piezo actuators are created by layering multiple piezo elements on top of each other, thus combining the effect of each element’s expansion to produce a useful movement and force. These actuators use the piezoelectric effect to generate linear displacements from 0.1 to 0.15 percent of the actuator length. They have a high force density—typically in the range of 30 N/mm2—resulting in useful force in the thousands of Newtons. Longitudinal piezo actuators also have high resonant frequencies, which makes them well-suited for dynamic applications.

Image credit: Noliac

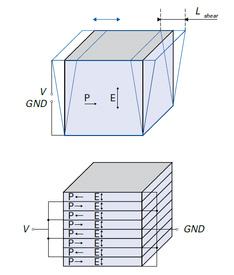

Shear actuators

Shear actuators are similar to longitudinal versions, in that they consist of multiple layers of piezo elements. But they differ in how the voltage is applied and the type of motion created. For shear piezo actuators, the elements are polarized horizontally and the electrical field is applied orthogonally. The resulting displacement occurs in the horizontal plane, creating a shear-type motion. The height of shear actuators is limited by shear stresses and bending, but they are often combined with longitudinal actuators in multi-axis systems.

Image credit: PI Ceramic GmbH

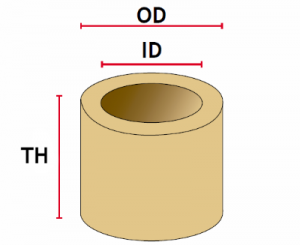

Tube actuators

Tube actuators have radial polarization and use the transverse piezoelectric effect to create displacement. These actuators can experience axial, radial, or lateral (bending) motion, depending on how the voltage is applied relative to the electrodes. Piezo tube actuators are not suitable for producing forces, but they provide micron-level travel for scanning microscopes and nanoliter dosing and pumping applications.

Image credit: Noliac

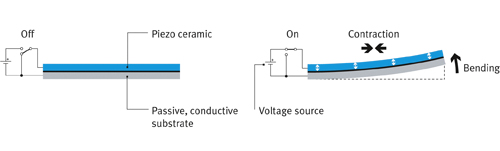

Contracting actuators

Flat actuators with two piezo elements can produce contracting (or expanding) motion when both elements act together. These actuators use the transverse piezoelectric effect and typically produce motion in just one direction. Contracting and expanding piezo actuators have small displacements—typically up to 20 microns—but can generate hundreds of Newtons force.

When a contracting actuator is mounted to a base or substrate, a bending actuator is created. In a bending actuator, the applied voltage causes one piezo element to expand while the other contracts. The result is a bending motion with relatively large displacement—typically several millimeters—but low force generation.

Image credit: Festo AG & Co. KG

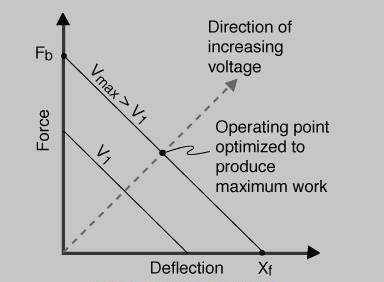

When specifying a piezo actuator, two parameters are usually considered—free deflection (Xf) and blocking force (Fb). Free deflection is the movement achieved when the maximum allowable voltage is applied and no force is generated. Similarly, blocking force is the maximum force that can be generated when the maximum allowable voltage is applied and the actuator is not allowed to move.

A piezo actuator is considered to be optimized for the application when it provides the required force at one-half its free deflection.

Piezo actuators are commonly used to replace solenoids in valves, pumps, and dispensing equipment, but they are also able to withstand extreme environments, such as the high vacuums found in semiconductor processing equipment and the strong magnetic fields found in MRI machines and aerospace components. Complete piezo stages can be created by incorporating piezo actuators with cross roller bearings or miniature guides, and these stages can be stacked to provide X-Y or X-Y-Z motion.

Feature image credit: Noliac

Thank you very much for explaining in detail about contracting actuators.

My question is that, how do we calculate the equivalent electric forces because of applied voltage or electric field. Also, the analogy of equivalent electric and mechanical forces in contract actuators?

Thank you again.