Rollers chains, as a mechanical power transmission method, and like any mechanical system, are subject to wear over time and with continued use. Just how much it wears depends on a number of factors including whether or not the chain is properly lubricated and the amount of loading, among other things.

So how does one tell if a roller chain has significant wear and what is too much wear? The best indicator of wear is chain elongation, which in reality indicates how much wear has occurred at the chain’s pins and rollers.

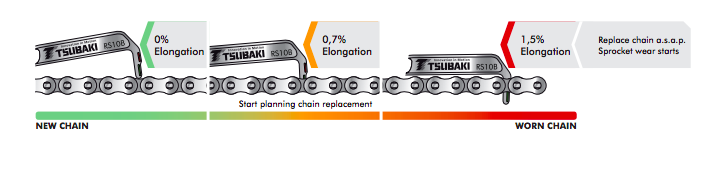

Roller chains eventually wear out to such an extent that they require replacement. A typical benchmark for this is at 1.5 to 2% (12.180 in./ft to 12.240 in./ft) elongation. Chains may work until they reach 3% elongation, but at that point they are at increased risk for suboptimal performance. For example, when chains wear out over time the pitch increases, making them looser and more compliant, which can add instability in the form of play into the system.

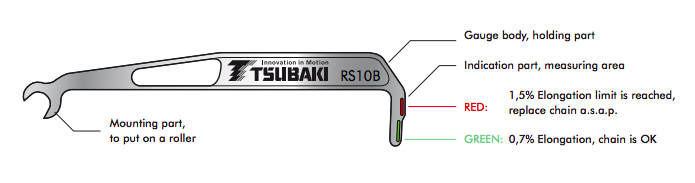

A simple and effective way to measure chain wear is using a chain-wear indicator. Basically, this is a kind of tool that measures wear in the chain as a function of a gap space between two rollers. The way you use it is to insert the tool (the chain wear indicator or gauge) in the space between two rollers. But first you’ll have to know the ANSI size of the chain you’re using in order to get a proper reading. If the tool stops at the ANSI size and doesn’t slip through, then the chain is still good to be used. If, however, the tool goes past that point and moves towards the next larger size, this is a sign that the chain has stretched beyond its normal level and should be replaced.

Leave a Reply

You must be logged in to post a comment.