According to the American Society of Mechanical Engineers (ASME), stiffness is:

The capacity of a mechanical system to sustain external loads without excessive changes of its geometry (deformations).

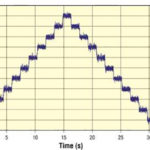

When we think of stiffness in traditional bearings with rolling elements, we’re typically considering the deflection of the carriage when a load is applied. For air bearings, which use a thin film of pressurized air to support the load, stiffness represents the bearing’s ability to maintain a consistent air gap — in other words, to resist changes in the air gap due to compression of the air caused by an applied load.

Image credit: New Way Air Bearings

Because air is a compressible medium, any change in loading will change the thickness of an air film between two surfaces — for air bearings, this means that an increase in load will cause a decrease in the air gap, due to the compression of air. Thicker air gaps are more compressible than thinner air gaps, so air bearings that are designed for high stiffness typically operate with extremely small air gaps, on the order of a few microns.

Image credit: Roger Cortesi, MIT

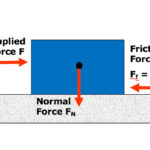

In addition to the size of the gap, another factor that affects air bearing stiffness is compensation, which is the method by which airflow into the air gap is controlled. Compensation works to create a restriction of airflow thru the orifice and into the gap, before the restriction of the gap itself. This restriction provides a restoring force when a load is applied or increased, allowing the bearing to resist compression of the air gap due to the increased load. In other words, the restricted airflow through the orifice provides “reserve” pressure that can maintain the air gap when external forces attempt to compress it.

Image credit: Aerotech Inc.

Like rolling element linear guides, air bearings can also be designed with preload to increase stiffness. There are several methods for creating preload on an air bearing: adding mass (weight), applying a vacuum to the air bearing, installing magnets on the moving and stationary parts, and combining two opposing bearings to create preload between them. Regardless of the preloading method, the result is the same: as a load is added to the bearing, the air gap compresses and the pressure increases, and so does the stiffness of the air film.

Leave a Reply

You must be logged in to post a comment.