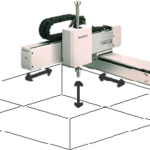

We’ve written several articles on this site about Cartesian robots, but let’s take a step back and define exactly what makes a robot a Cartesian robot, as opposed to another type of robot or multi-axis system.

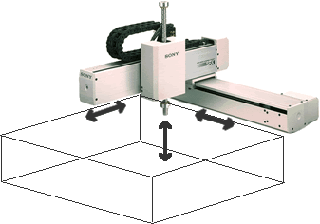

Image credit: RobotWorx

First, a Cartesian system is one that moves in three, orthogonal axes — X, Y, and Z — according to the Cartesian coordinates. (Although it should be noted that a rotary axis — in the form of an end effector or end of arm tooling — is sometimes included on the outermost axis of a Cartesian robot.)

What makes a Cartesian robot a robot is that the axes perform coordinated motion, through a common motion controller.

The axes of a Cartesian robot are made from some form of linear actuator — either purchased as a pre-assembled system from a manufacturer or custom-built by the OEM or end user from linear guide and drive components.

Simple, right?

The ISO 8373:2012 standard defines an industrial robot as:

An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications.

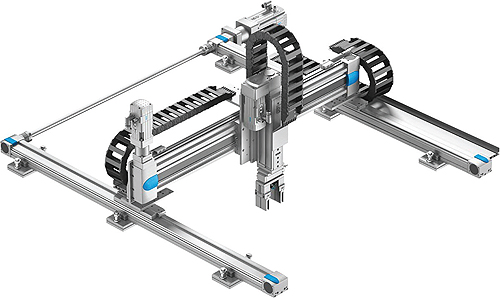

But not every linear system that works in the X-Y, or X-Y-Z axes is a Cartesian robot. One notable exception is a type of robot that employs two base (X) axes in parallel. This configuration — 2X-Y or 2X-Y-Z, for example — moves the robot out of the Cartesian category and into the category of gantry robots.

The primary difference between gantry and Cartesian robots is that a Cartesian robot uses one linear actuator on each axis, whereas a gantry robot is always constructed with two base (X) axes, with the second (Y) axis spanning them. This configuration prevents the second axis from being cantilevered (more on that below) and allows gantries to have much longer stroke lengths — and in many cases, larger payloads — than Cartesian robots.

Image credit: Festo Group

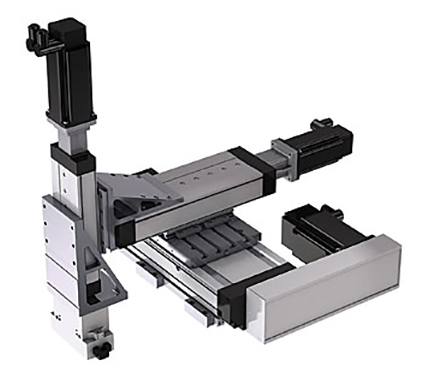

The second type of multi-axis linear system that does not fall under the definition of Cartesian robot is the XY table. The difference between Cartesian robots and XY tables lies in the mounting and loading arrangement. In a Cartesian robot, the second or third (Y or Z) axis is cantilevered, being supported at only one end by the axis below it. In addition, the load on the outer axis is generally cantilevered from that axis.

This arrangement creates not only a moment load on the outer axis, due to the applied load, but also a significant moment load on the supporting axis, due to the combined effect of the applied load along with the outer axis. The mounting and loading arrangement limits the load-carrying capability of Cartesian robots and is a primary factor in determining the maximum stroke length for the outer (cantilevered) axis.

In contrast, XY tables consist of two axes centered on top of each other, often with similar stroke lengths. In addition, the load is generally centered on the Y axis. This axis configuration and load positioning results in very little cantilevered loading on either axis (and often no cantilevered loading on the Y axis).

Image credit: Dover Motion

Cartesian robots overlap SCARA and 6-axis (articulated) robots in some technical specifications and can be applied in some of the same applications, but Cartesian robots have several benefits over SCARA and 6-axis types. First, Cartesian designs provide a rectangular work envelope in which a significant percentage of the robot’s footprint is used as active work area. SCARA and 6-axis types, on the other hand, have circular or oval work envelopes that often result in a lot of dead (unused) space, especially when the required travel, or reach, is very long.

Image credit: Bosch Rexroth Corp.

Cartesian robots can be constructed from virtually any type of linear actuator with any variety of drive mechanisms — belt, ball or lead screw, pneumatic actuator, or linear motor. (Note that rack and pinion drives are also possible, but are more commonly used in gantry systems with very long strokes.) This means they can, and often do, have better positioning accuracy and repeatability than SCARA and 6-axis types. Cartesian robots also have an ease-of-use advantage in terms of programming because their kinematics are simpler (three Cartesian axes, rather than multiple rotational axes).

In the recent past, pre-assembled Cartesian robots were rare, with most units being custom-built by an OEM, a robot integrator, or even the end user. But now, many linear actuator manufacturers also provide pre-configured, pre-assembled Cartesian systems, with myriad options to fit common travel, payload, speed, and precision requirements. And manufacturers of traditional 6-axis and SCARA robots are getting in on the action as well, recognizing that for many industrial automation and assembly applications, Cartesian robots offer a better tradeoff between load capacity and footprint than SCARA and 6-axis designs.

For more news, analysis, and education on all things robot-related, visit our sister site at https://www.therobotreport.com.

Leave a Reply

You must be logged in to post a comment.