A direct drive motor is any motor — rotary or linear — in which the load is connected directly to the motor, without mechanical transmission elements such as gearboxes or belt and pulley systems. In other words, the motor directly drives the load.

Direct drive rotary motors

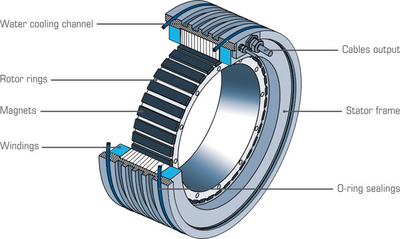

Rotary direct drive motors are often referred to as torque motors because of their ability to produce high torque at low speeds, even when stalled. Torque motors tend to be brushless, permanent magnet synchronous motors — much like a traditional servo motor, but with a large number of poles. They’re often provided as frameless designs, meaning they don’t include a housing, bearings, or feedback device, with these components being purchased separately and integrated by the user.

Image credit: ETEL S.A.

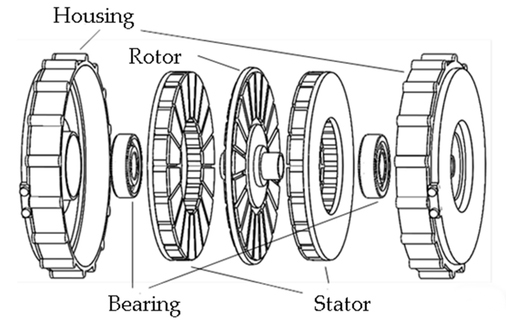

Another type of rotary direct drive motor is the pancake motor, also referred to as a Lorentz force motor or printed armature motor. These motors are brushed DC motors in which the armature windings are printed on a disc of non-magnetic, insulating material. The armature disc is placed between two stator discs that have permanent magnets arranged with alternating north and south poles. The magnetic flux runs axially along the length of the motor and current runs radially (rather than axially, as in a traditional motor). This causes torque to be produced around the motor’s axis, according to the Lorentz force.

Image credit: Energies, Vol. 9, Issue 4: April 2016

Piezo motors and voice coil motors (actuators) are also classified as direct drive motors, albeit highly specialized types, due to the direct coupling between the load and the piezo or voice coil mechanism.

Linear direct drive motor variations

Linear direct drive motors are often simply referred to as “linear motors.” These include ironless and iron core versions, depending on the construction of the primary part (the part that contains the windings). Ironless versions have a primary made of windings embedded in an epoxy resin, whereas iron core versions have windings that are mounted in an iron lamination stack. Another distinguishing feature of a linear direct drive motor is whether it has a flat or a tubular construction.

Flat linear direct drive motors

Image credit: Parker Hannifin Corporation

Ironless flat linear motors have a flat magnet (secondary part), with a primary part, or forcer, consisting of coils mounted to an aluminum plate. These motors have excellent velocity control but produce less force than other designs. Another construction variation for ironless motors uses two magnet tracks facing each other (sometimes referred to as U-channel or air core linear motors). The ironless secondary part, or forcer, rides between the magnet tracks. These motors have no cogging and can produce very high acceleration and deceleration rates.

Flat iron core linear motors can be either slotted or slotless, with slotted iron core designs being the more common variation. The secondary part of a slotted iron core linear motor consists of a back iron plate and iron teeth, or laminations, around which the coils are wound. They have the highest force capabilities, but they can experience significant cogging.

Slotless designs are considered to be a hybrid between ironless and traditional slotted iron core designs, because they have coils that are wound without iron lamination but are mounted to a back iron plate. The secondary part is often contained in an aluminum housing. These motors have less cogging and lower inertia than slotted iron core designs, but they also have lower force capability.

Another version of the flat linear motor is the linear stepper motor.

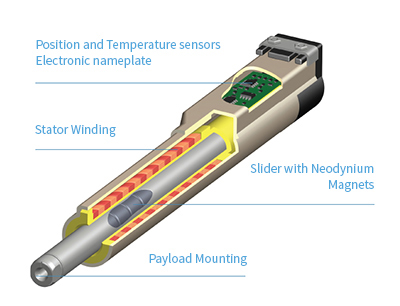

Tubular linear direct drive motors

Another construction variation of the direct drive linear motor is to contain the magnets within a cylindrical tube and house the windings in a forcer, or thrust block, that surrounds the tube. Like their flat counterparts, tubular linear motors can be constructed with or without iron in the secondary part (i.e. iron core or ironless). The primary benefit of a tubular linear motor is that its symmetrical designs allows all the magnetic flux to be used for generating thrust force.

Image credit: LinMot USA, Inc.

Direct drive motor benefits and applications

Image credit: TorqueTec GmbH

Regardless of its design — rotary or linear, flat or tubular, iron core or ironless — a direct drive motor has the benefit of eliminating mechanical components that can introduce backlash or compliance and degrade positioning accuracy and repeatability. The elimination of mechanical connections also reduces load inertia and allows more dynamic moves — i.e. higher acceleration and deceleration rates with heavier loads — with less overshoot and oscillation. Direct drive motors also have lower noise production than conventional motors, which is important for noise-sensitive applications, like those in the medical and laboratory industries.

Without additional transmission elements, direct drive motors tend to be more compact than traditional motors, making them easier to integrate into machines and systems with tight spaces. And with fewer mechanical components (often, the only wear components are linear guides), maintenance is reduced and mean time between failures (MTBF) is increased.

Rotary direct drive motors are used to drive goniometers, gimbals, rotary tables, and SCARA and 6-axis robot arms. Many designs have a center bore, which allows electrical cables and pneumatic lines to be routed through the center of the motor.

Image credit: Dunkermotoren GmbH

Linear versions are used in numerous automation applications, including packaging machines that require rapid strokes on a continuous basis, machine tools that require extreme positioning accuracy and high load carrying capability, and semiconductor manufacturing equipment that requires ultra-smooth and precise motion.

Feature image credit: Kollmorgen

Leave a Reply

You must be logged in to post a comment.