A linear voice coil motor (also referred to as a “voice coil actuator” or “linear DC motor”) is a simple yet very precise type of electric motor, consisting of just two primary parts – a coil and a magnet. When current is applied to the coil, a force is generated. The magnitude of the force is directly proportional to the applied current and is nearly constant throughout the stroke, with a dropoff of less than 5 percent near the ends of the movement.

The force produced by a voice coil motor is known as the Lorentz force, given by the following equation:

F = k*B*L*I*N

Where:

F = force (N)

k = force constant

B = magnetic flux density (tesla)

L = length of wire (m)

I = current (amps)

N = number of conductors

In addition to the magnitude of the force being directly proportional to the applied current, the direction of the force – and, therefore, the direction of linear displacement – depends on the direction of the current. In other words, reversing the polarity of the current changes the direction of motion.

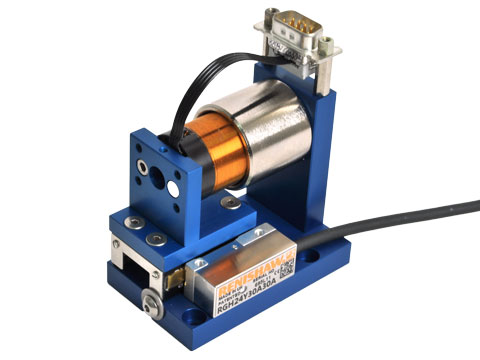

Voice coil motors come in both moving coil and moving magnet versions. Designs with a moving coil have the benefit of lower moved mass and lower inertia. But the coil generates heat, so if the load is sensitive to temperature fluctuations, attaching it to the coil could be detrimental. In these cases, a moving magnet design may be a better option. Regardless of moving coil or moving magnet, when used with a position sensor, voice coil motors can achieve positioning accuracies of 1 micron (0.001 mm) or less.

Image credit: BEI Kimco

A hollow core linear voice coil motor (or actuator) is simply a voice coil motor that has an axial hole through its center. Both moving coil and moving magnet motors can be provided as hollow core designs, and manufacturers offer a wide range and combination of housing (magnet) diameters and bore diameters, in addition to stroke lengths up to 5 inches (127 mm).

The hollow core design allows the OEM fixture or cables to be routed through the motor, and the elimination of material reduces the weight and inertia of the assembly. A common application for hollow core voice coil motors is laser beam focusing, with the laser beam passing through the axial hole in the motor. Other applications include optical focusing, drilling, and scanning.

Image credit: H2W Technologies

Leave a Reply

You must be logged in to post a comment.