In single-axis motion systems, travel is typically either linear (in a straight line) or rotary (in a partial or complete circle). But some applications call for a system that combines straight sections of motion with curved sections — referred to as curvilinear motion.

Curvilinear systems generally take one of two forms: simple, constant-radii sections (such as a 90- or 180-degree turn) together with straight sections, or variable-radii sections (think of a free-form, squiggly line) combined with straight sections. The former is typical of a conveying-type application, often used when a part needs to be moved around an assembly or inspection station. The latter is often found when parts or components need to be moved in a generally straight line, but with some deviations to avoid obstacles. Applications where obstacles may necessitate variable-radius curvilinear motion are the positioning of monitors or tools at assembly stations or ergonomic adjustments of equipment at work stations to suit a wide range of operators and uses.

This video from Rollon shows a curvilinear guide rail being used to adjust the position of an optometry machine to suit the individual patient and doctor.

Carriage options for combined linear and curved motions

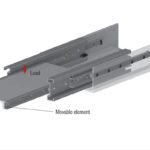

One of the challenges of curvilinear motion is that the moving component — the carriage or slider — must be able to operate around the curves and through the transitions between straight and curved sections. For this reason, many curvilinear systems use wheels or rollers to guide and support the load. The main benefit of wheels and rollers in combined linear and curved motion is that they don’t require the highly accurate running surfaces that recirculating bearings require. Roller carriages can also be adjusted to add preload and stiffness, and both wheels and rollers are able to withstand environments with particulate contamination, such as dust and chips.

Image credit: Rollon Corp.

Plain bearings are also used in curvilinear motion, and thanks to their relative ease of manufacturing, can be provided in custom designs tailored to a specific curvilinear system. Plain bearings are also inherently self-aligning, so the risk of binding and excessive wear due to curved motion sections is reduced.

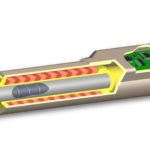

While recirculating bearings are sometimes used in curvilinear systems, they only operate well for curves with large radii. And while they can work in systems with both straight and curved sections (as long as the curve is sufficiently large), they are very sensitive to transitions between sections, which can cause excessive pulsations in the rolling elements and damage to the bearing seals. However, recirculating bearings are the best option when high load capacity, excellent rigidly, and good running accuracy are required.

Image credit: THK

Drive options for curvilinear systems

The most common drive mechanisms for curvilinear systems are belt and chain drives. Belts and chains are ideal for curvilinear applications since they can navigate both straight and curved paths — with constant- or variable-radii — and they allow multiple carriages or sliders to be attached to one system and move in synchronization.

This video from Hepco Motion shows that not all curvilinear systems are for small, lightweight applications. Here, a chain-driven curvilinear system is used in conjunction with 6-axis and SCARA robots on a 20m-long assembly station for the electronics industry.

Curved, curvilinear, or contoured?

Guides and tracks that provide curved motion are often put in the same category as curvilinear guides, but curved guides only provide motion that occurs along a radius, and don’t include straight sections of motion.

Curvilinear guides are also confused sometimes with contouring, or contoured motion. Contouring is a type of motion control used in multi-axis linear systems (such as Cartesian robots or X-Y tables) that creates radii and rounded corners in rectilinear coordinates.

Leave a Reply

You must be logged in to post a comment.