Roller screws are often thought of as the standard planetary design, but several variations exist, including differential, recirculating, and inverted versions. Each design offers unique benefits in performance capabilities — load capacity, torque, and positioning — but the inverted roller screw’s primary strength is its ability to be easily integrated into actuators and other subassemblies.

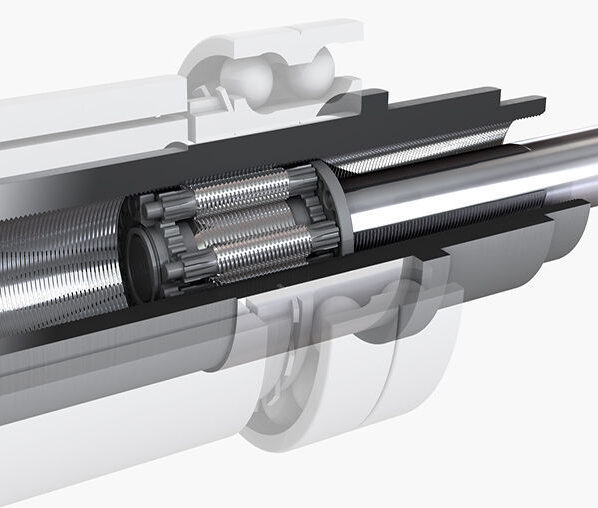

Recall that a standard roller screw (also referred to as a planetary roller screw) uses threaded rollers, with the ends of the rollers being toothed to mesh with geared rings at each end of the nut. For an inverted roller screw, the functions of the screw and the nut are interchanged, or inverted. The nut is essentially a tube with a threaded inner diameter, and rather than its length being just sufficient to accommodate the rollers and mating geared rings, the nut is made the length of the stroke. And the screw shaft — rather than being threaded along its entire length — is threaded for a length just equal to that of the rollers.

Image credit: Ewellix

So when the screw shaft is turned, instead of the nut and rollers translating along the length of the screw, the rollers remain axially stationary on the screw (that is, the rollers and nut don’t travel along the screw length). Instead, turning the screw shaft causes the rollers — and the screw — to translate along the length of the nut. Alternatively, it is possible with an inverted roller screw to drive the nut and hold the screw (and rollers) axially stationary.

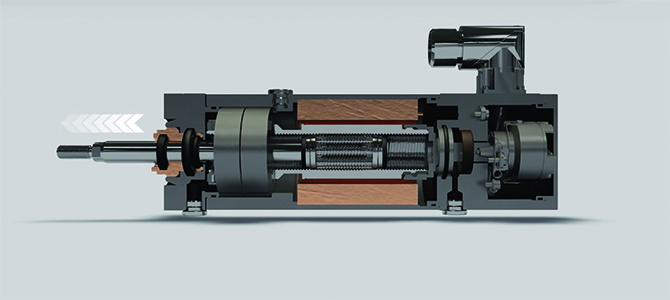

This animation from Rollvis shows the inner workings of an inverted roller screw.

With the geared rings that normally reside at the end of the nut now positioned at the ends of the threaded section of the screw, the nut diameter can be made slightly smaller than that of a similar sized planetary roller screw. Although machining the threads inside the relatively long nut body can be difficult, inverted roller screws can have fewer starts than standard planetary roller screws, meaning they can use a larger thread and, in turn, provide higher load capacities than standard designs.

Inverted roller screws are ideal for thrust rod style actuators, in which a push rod extends and retracts from the actuator housing. And because a significant portion of the screw shaft is not threaded (only the section where the rollers reside is threaded), the shaft can be customized to suit the actuator’s design and application requirements. The inverted design also makes it relatively easy for actuator manufacturers to attach magnets to the roller screw nut and implement it as the rotor for an integrated motor-screw assembly.

Image credit: Diakont

Leave a Reply

You must be logged in to post a comment.