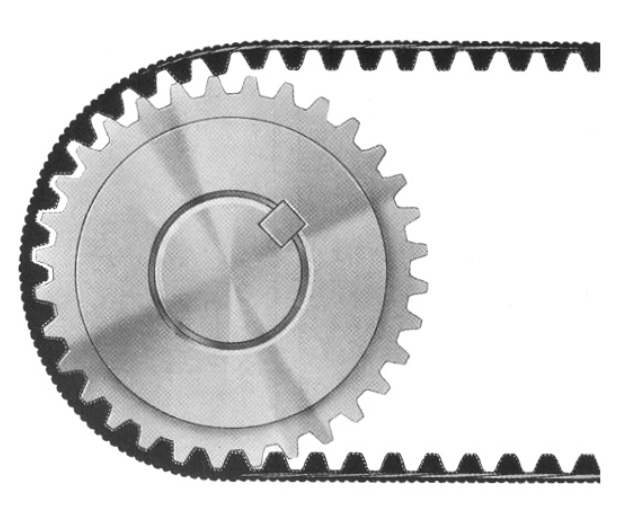

Synchronous belts (also referred to as toothed, cogged, timing, or high torque belts) use profiled teeth that mesh with a pulley or sprocket to deliver power transmission – most notably for applications that require high torque. Where V-belts rely on friction between the sidewalls of the belt and the sides of the pulley to transmit power, synchronous belts rely on the engagement between pulley teeth and belt teeth to transmit power.

Image credit: Gates Corporation

While synchronous belts can transmit high torque without slippage when properly tensioned, using a belt with insufficient tension for the required operating parameters can cause the belt to jump teeth – a condition known as belt ratcheting.

When belt tension is too low, the belt may begin to “self-tension,” with the belt teeth riding out of the pulley and causing increased tension on the belt. When this tension becomes too high, it will force the belt back down into the pulley grooves, which results in a brief but pronounced period of bending that can damage the belt tensile cords in a manner referred to as crimping. However, if the force of the “self-tension” does not cause the belt to slip back into the pulley grooves, the belt will ratchet, which can also cause crimping to the belt tensile cords and result in premature failure.

Image credit: Gates Corporation

Proper tension of synchronous belts is the tension at which the belt will transmit the required power without ratcheting when the drive system experiences full load.

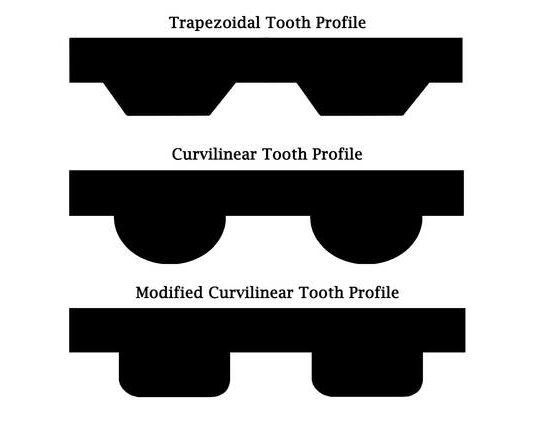

Synchronous belts have three general tooth profiles: trapezoidal, curvilinear, and modified curvilinear. Trapezoidal profiles are arguably the most common and provide good force capabilities with low backlash. Curvilinear (also referred to as “high torque drive”) profiles have a geometry that is rounder and deeper than trapezoidal profiles, with a higher flank angle and greater contact area. This allows for better stress distribution and higher overall loading on the belt, but at the expense of higher backlash.

Modified curvilinear tooth profiles have a smaller tooth depth and an even greater flank angle, which provides the highest load carrying capacities of the three tooth profiles. But one of the primary advantages of this design is that the areas of the belt between teeth share load-carrying duties with the teeth that are engaged in the pulley. This gives modified curvilinear belts the best anti-ratcheting properties, even under extremely high loads.

Nice explanation about the synchronous belt drives and the belt ratcheting.