The discrete, step-by-step movements that give a stepper motor its accurate positioning capability can also lead to some undesirable performance characteristics — namely, vibration and audible noise due to resonance.

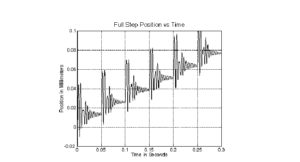

Stepper motors naturally exhibit small vibrations with each step, due to the inertia of the moving rotor, which causes the motor to slightly overshoot (or, in some cases, undershoot) the step position and oscillate until it “settles” at the correct step angle. If the frequency of these oscillations matches the motor’s natural frequency, resonance occurs, which leads to audible noise, vibration, and — in extreme cases — lost steps or stalling.

While manufacturers use several design techniques to reduce resonance in stepper motors — such as special winding configurations or low-inertia rotor designs — there are also steps the user or OEM can take to reduce resonance in stepper motor systems.

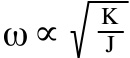

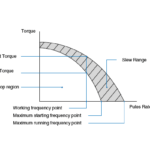

The resonant frequency of a stepper motor (ω) is proportional to the square root of the motor’s torque stiffness (K) divided by its inertia (J). Changing either parameter will change the motor’s resonant frequency.

Reduce step size

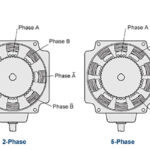

The most widely recommended method to reduce stepper motor resonance is to make the motor’s step size smaller. This can be done through microstepping or by using a 5-phase stepper motor.

Microstepping is a control method for stepper motors that electronically divides each step into smaller increments. With smaller step sizes, the build-up and decay of current in each winding is more gradual and there’s less torque variance between steps. This means that position overshooting is less extreme, settling time is lower, and vibrations and noise are greatly reduced.

Image credit: New Japan Radio Co., Ltd.

Similarly, a 5-phase stepper motor reduces the motor’s step size by decreasing the offset between stator and rotor teeth to 1/10 of a tooth pitch, giving a step angle of 0.72 degrees (as compared to a step angle of 1.8 degrees for a standard 2-phase stepper motor). Again, the smaller step size means less torque is required for moving the rotor to the next position, so current build-up and decay are less extreme, and overshooting is reduced.

Add damping

Image credit: Lin Engineering

Mechanical dampers — whether internal viscous dampers or external damping devices — can eliminate or reduce stepper motor resonance by changing the inertia of the system, which in turn shifts the motor’s resonant frequency. And if the motor does experience resonance, dampers absorb some of the vibration energy that occurs as the motor oscillates and settles at the step position.

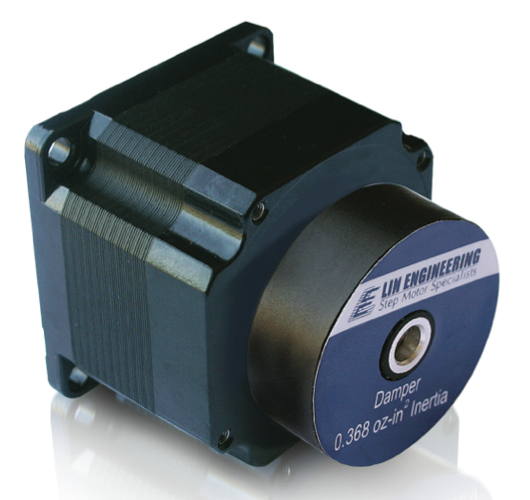

Use a gearbox

While gearboxes are typically used for increasing torque from the motor, the addition of a gearbox also increases the inertia of the motor side of the drive train, which reduces the motor’s resonant frequency (see equation above). Adding a gearbox to a stepper motor also means the motor will need to operate at higher speed — often outside its resonant frequency range.

Image credit: Oriental Motor USA

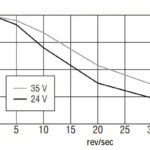

Use a chopper drive

Another way to reduce stepper motor resonance is to precisely control the current to the motor so that it receives only the amount of current (and, therefore, torque) required for each step. This is often done with a type of stepper drive known as a chopper drive, which uses pulse-width-modulation to vary the output voltage and current to the motor and precisely control motor torque.

Feature image credit: Dover Motion

Leave a Reply

You must be logged in to post a comment.