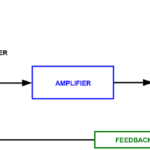

The short answer is: There is no single “type” of servo motor. The term “servo” simply means the motor operates in a closed loop control system that uses feedback from an encoder or resolver (typically integral to, or mounted on, the motor) to compare the motor’s actual position, velocity, or torque to the commanded value. Note that this definition does not specify the motor’s basic construction or operation.

But some motor types are better suited for servo applications — which often involve high-precision moves with well-regulated speed or torque — than others. Here’s an overview of the various types of motors and why some motor designs perform better than others in servo applications.

The first distinction that’s generally made between various motors is whether they run on AC or DC power. The fundamental difference in operation between an AC and a DC motor is that the speed of an AC motor is controlled by the frequency of the applied voltage and the number of magnetic poles in the motor. For a DC motor, speed is directly proportional to the supply voltage, given a constant motor load. As you’ll see below, both AC and DC motors can be used as servo motors.

AC motors: Synchronous or asynchronous

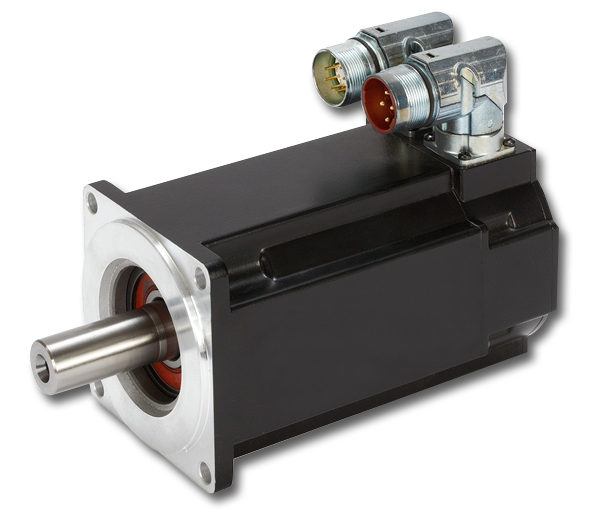

Image credit: Kollmorgen

AC motors can be further divided into two categories: synchronous and asynchronous, depending on the speed of their rotating field. For a synchronous motor, the rotor turns at the same rate as the stator’s rotating magnetic field, which is referred to as the synchronous speed. Synchronous AC motors have a high torque density and excellent performance in dynamic applications, so they’re often used in servo systems. Synchronous AC motors are also referred to as permanent magnet AC (PMAC) or brushless AC (BLAC) motors.

In an asynchronous motor (also referred to as an induction motor), the rotor turns at a speed slower than the stator’s rotating magnetic field. Induction motors are often used with variable frequency drives to achieve speed control, but they generally don’t incorporate feedback, so they’re not true servo devices.

DC motors: Brushed or brushless

DC motors are subdivided into brushed and brushless versions, depending on whether they’re mechanically commutated (with brushes and a commutator) or electronically commutated (via Hall sensors or other feedback).

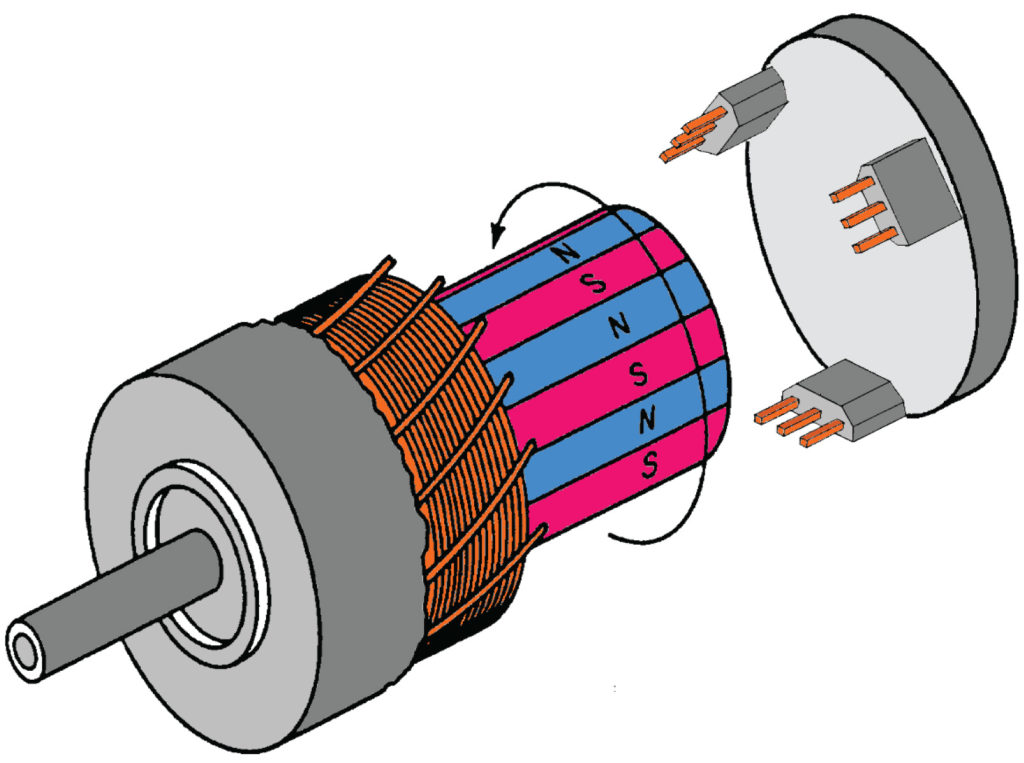

Image credit: Honeywell International, Inc.

Both brushed and brushless DC motors can be used in servo systems, although brushed motors are less common in servo applications due to the wear and associated maintenance of the brushes and commutator.

When brushed motors are used in servo applications, the configuration of choice is typically a permanent magnet stator (as opposed to a wound stator), which is a design often referred to as a permanent magnet DC (PMDC) motor.

Brushless DC (BLDC) motors, on the other hand, are well-suited for servo applications due to their high efficiency and reliability, low rotor torque (which improves dynamic response), and linear speed-torque relationship.

Are synchronous AC and BLDC motors the same?

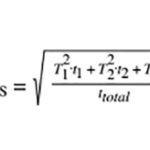

Like the synchronous AC motors described above, BLDC motors also use permanent magnets on the rotor and run at synchronous speed. And technically, the voltage that runs a BLDC motor is converted from AC to DC through a DC bus and electronic circuitry. So many experts argue that these two motor types are the same technology, and group them together in the category of permanent magnet synchronous motors (PMSM). But the stator windings differ between synchronous AC motors and brushless DC motors, and this difference affects their operation and performance.

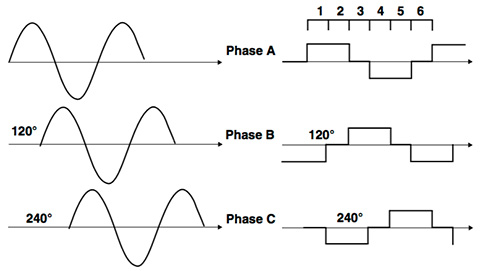

Image credit: STMicroelectronics

In BLDC motors, the stator coils are trapezoidally wound and produce a trapezoidal back-EMF waveform, which tends to produce audible noise. Commutation is achieved in six steps (every 60 degrees), which generates torque ripple. Synchronous AC motors, on the other hand, have sinusoidally wound stators and use continuous, sinusoidal commutation, which eliminates the torque ripple experienced by BLDC motors. This makes synchronous AC motors the preferred choice for high-performance industrial servo applications.

Leave a Reply

You must be logged in to post a comment.