Recirculating ball and roller guides are the backbone of many automation processes and machines, thanks to their high running accuracy, good rigidity, and excellent load capacities — characteristics made possible by the use of high-strength AISI/ASTM 52100 chrome steel (commonly referred to as bearing steel) for the load-bearing parts. But because bearing steel isn’t corrosion-resistant, standard recirculating linear guides aren’t suitable for most applications that involve liquids, high humidity, or significant temperature fluctuations.

To address the need for recirculating guides and bearings that can be used in wet, humid, or corrosive environments, manufacturers offer corrosion-resistant versions. But the level of corrosion-resistance offered by a linear guide or bearing varies, depending on the materials and processes used in its manufacture.

Since there’s no standard or industry-accepted definition of corrosion-resistance, we’ve put together a breakdown of the three most common levels of corrosion-resistance offered by manufacturers of recirculating linear guides and bearings, along with their primary uses.

1 – External metal parts made of corrosion-resistant steel

The first line of defense against corrosion is to address the parts of the bearing system that will be exposed to the environment — namely, the bearing housing and guide rail. These components can be made of martensitic stainless steel (400 series). Martensitic stainless steels are ideal for bearing applications because they can be treated for dimensional stability and hardened to withstand the extreme pressures and Hertzian stresses that are inherent in recirculating linear bearings — especially those that use balls at the rolling elements.

Some manufacturers offer linear guide rails made of austenitic stainless (300 series), which provides better corrosion resistance than martensitic stainless. However, austenitic stainless steel cannot be sufficiently hardened and has lower speed and load capacities, making it less suitable for load-bearing surfaces than martensitic stainless.

2 – All metal parts made of corrosion-resistant steel

For applications with exposure to salt water, acids, alkaline solutions (bases), or steam, it may be necessary to use stainless steel for all metal parts — both internal and external to the bearing block. Because they carry the load, the balls or rollers are commonly made of martensitic stainless (as is the bearing housing), while the non-load-bearing parts, such as fasteners, end plates, and lubrication parts, are made from austenitic stainless.

In this configuration, it’s important to note that the load bearing components (particularly the raceways and rolling elements) are made from stainless steel rather than bearing steel, so bearing load capacities are reduced.

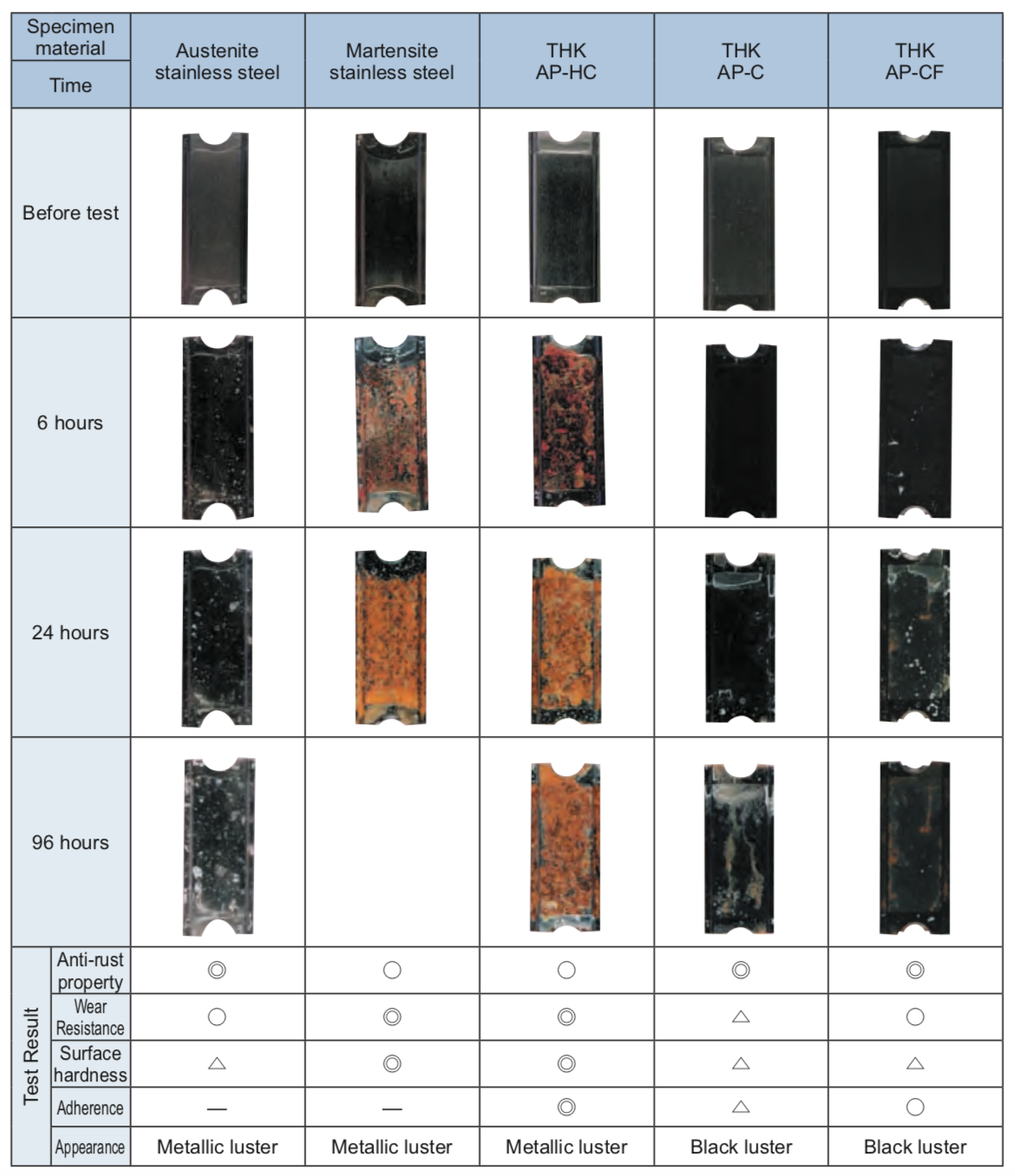

3 – External metal parts chrome plated

For the highest level of corrosion protection, all exposed metal surfaces can be plated — typically with a hard chrome or black chrome plating. Some manufacturers also offer black chrome plating with a fluoroplastic (Teflon, or PTFE-type) coating, which provides even better corrosion protection. Chrome platings can be applied to most metals, including stainless steel.

The downside of plating a linear bearing or guide rail is that it adds thickness to the plated surfaces, so it changes the height and width tolerances of bearing assemblies.

AP-HC = hard chrome plating

AP-C = black chrome plating

AP-CF = chrome plating with fluorine resin coating

Double circle = best performance

Circle = good performance

Triangle = acceptable performance

Image credit: THK

Other options for corrosion resistance

In addition to stainless steel and chrome platings for linear guides and bearings, there are other options that allow designers and users to address corrosive environments. One is to use a recirculating linear bearing with a housing (body) made of aluminum. This design may be sufficient for applications where wet or corrosive conditions are possible but not likely, or where the components won’t be directly exposed to the corrosive agents. Aluminum bearings have a lower weight and are often lower cost than other corrosion-resistant options, but they’re typically offered only in a small range of sizes, preloads, and accuracy classes, and they have a lower static load capacity than steel or stainless steel versions.

Two other corrosion-resistant options for linear guides — especially for applications that require FDA or USDA compliance* — are electroless nickel and nickel-cobalt platings. In addition to meeting standards set by the USDA and FDA, both platings offer excellent corrosion resistance and hardness and can be used on steel and stainless steel components.

*Note that approval for these coatings is typically obtained on an application-specific basis and depends on the coating formulation and its use.

Leave a Reply

You must be logged in to post a comment.