In linear systems, backlash and hysteresis are often referred to as the same phenomenon. But while they both contribute to lost motion, their causes and methods of operation are different.

Backlash: The enemy of linear systems

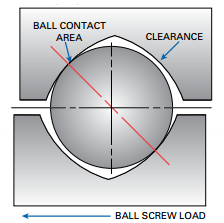

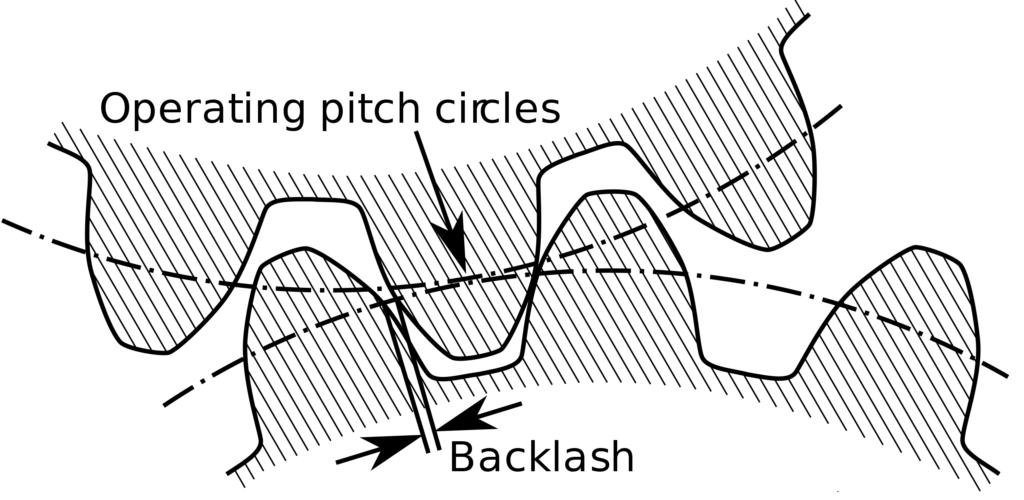

Backlash is caused by clearance, or play, between mating parts, which introduces a dead band when the direction of travel is reversed. In the dead band, no movement occurs until the clearance between mating parts is eliminated.

Components that typically experience backlash include ball screws, lead screws, belt and pulley systems, and gears. In recirculating bearing systems, applying preload can reduce or eliminate backlash by removing the clearance between the balls (or rollers) and the raceways. Some non-recirculating systems use alternative methods, such as springs or specially-designed lead screw nuts, to reduce or eliminate backlash.

Or is it?

Although backlash is generally viewed as a negative characteristic of mechanical systems, it isn’t always detrimental. First, producing completely backlash-free components is expensive and, in most cases, impractical. And backlash-reducing methods inevitably increase friction and wear. If some backlash can be tolerated in the application, the available components will be less expensive, more readily available, and in many cases, will have longer life. In gears and gearboxes, some backlash is necessary to allow the gears to mesh without over stressing gear teeth and increasing friction.

Image credit: wikipedia.org

What is hysteresis?

Hysteresis is most often associated with magnetic systems and manifests in electrical motors as hysteresis loss. Simply stated, hysteresis is the relationship between the reaction of a material to an initial load (or magnetizing force) and the material’s recovery once the load (or magnetizing force) is removed. For example, when iron is magnetized by an external field, the magnetization of the iron lags behind the magnetizing force. When the magnetizing force is removed, the iron retains some amount of magnetism. In other words, the iron doesn’t fully recover to its non-magnetized state unless an opposing magnetizing force is applied.

Image credit: NDT Resource Center

In mechanical systems, hysteresis is related to a material’s elasticity. For example, as steel balls in a ball nut move from the non-load-bearing zone to the load-bearing zone, the forces they experience increase, causing them to deform slightly. But because of the elastic properties of the steel, the balls don’t fully return to their original shape when they move back into the non-load-bearing zone of the nut. This persistent, microscopic deformation is due to hysteresis.

Hysteresis also affects the behavior of drive shafts in mechanical systems. When torque (a torsional force) is applied to a shaft, it produces an internal stress and causes the shaft to change shape. This change in shape is referred to as strain (or, torsional strain, in the case of torsional loading). In perfectly elastic materials, the relationship between stress and strain is linear. But few materials are perfectly elastic, and the inelasticity of materials gives them a non-linear stress-strain curve. This non-linear behavior as forces increase and decrease is referred to as hysteresis.

When does hysteresis matter in linear systems?

In all but the highest-precision mechanical stages, hysteresis has a negligible effect on positioning accuracy and repeatability, and in most cases, the effects of backlash greatly surpass those of hysteresis. However, piezo actuators, which rely on material strain to produce motion, can experience hysteresis of 10 to 15 percent of the commanded movement. Operating piezo actuators in a closed-loop system can reduce or eliminate hysteresis effects.

Feature image credit: Nexen Group, Inc.

In some instances Intentional hysteresis can also be used as a dead zone, Adding just enough to cover the feedback sensor’s noise can stabelize a system and reduce hunting, if derivative feedback is not adequate. Backlash is different in that it is often unavoidable and may contribyute to system errors.