Bearing damage, and ultimately, failure, can be caused by a variety of conditions, including improper mounting, poor lubrication, and overloading, to name a few. The mode of damage — what actually happened to the bearing as a result of detrimental conditions — is characterized by visible features, such as discoloration, wear marks, or pitting, on the rolling element and raceway surfaces. However, different modes of damage can produce visually similar results, although their causes and long-term effects may not be the same. This is why it’s important to understand the operating conditions when investigating bearing damage, as they can provide additional clues regarding the root cause of the damage.

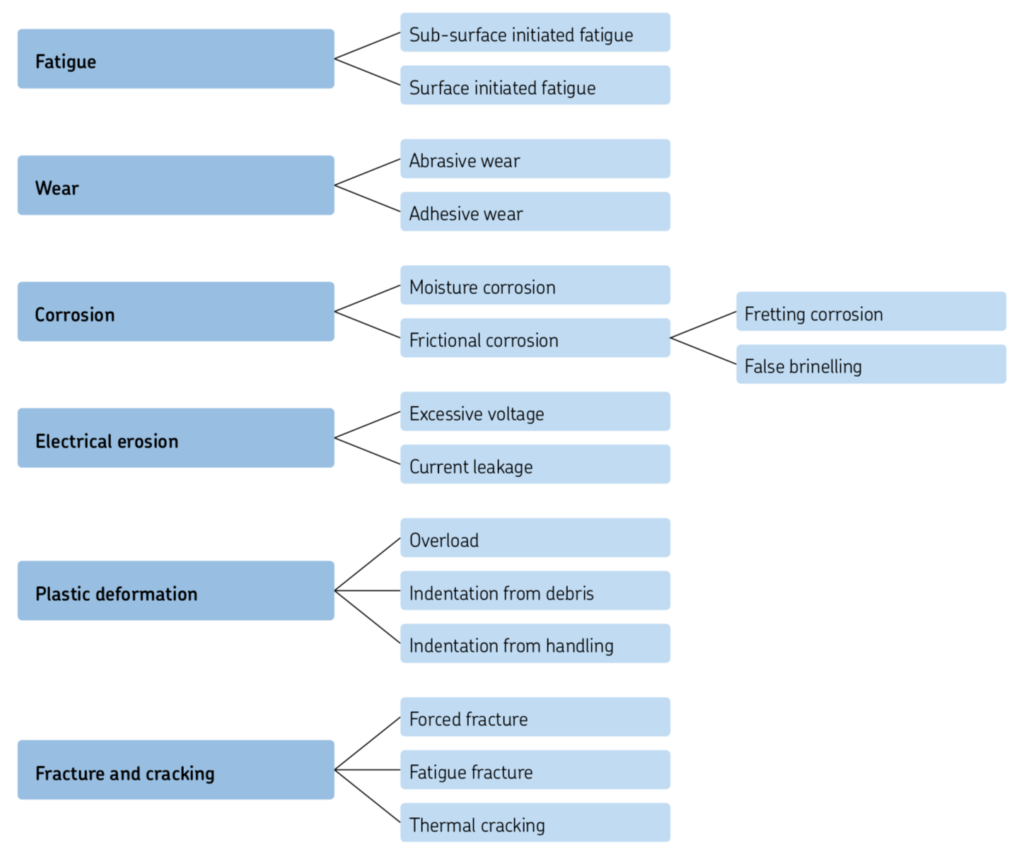

The ISO standard 15243:2017, Rolling bearings – damage and failures – terms, characteristics, and causes, classifies failure modes for rolling bearings made of standard bearing steels. The standard defines six primary damage/failure modes, along with various sub-modes.

Image credit: SKF

When discussing bearing damage — especially in the context of linear bearings — three terms that come up quite often are brinelling, spalling, and fretting. Let’s look at their causes and the differences between them.

Brinelling

Image credit: Schaeffler

A type of plastic deformation caused by repeated, localized impacts or static overload, brinelling causes surface damage to a bearing raceway in the form of regularly-spaced indentions. (These indentions are similar to those produced in a Brinell hardness test, hence the name “brinelling.”)

Notice that brinelling is not explicitly listed in the ISO damage/failure modes shown above, but it occurs in the “Plastic deformation” subcategories of “Overload” and “Indentation from handling” (due to materials being dropped, for example).

Spalling

Spalling is the result of surface or sub-surface fatigue, which causes fractures to form in the running surfaces. When the rolling elements travel over these cracks, pieces, or flakes, of material break away. (Spalling is also referred to as “flaking,” “peeling,” or “pitting.”)

In the ISO damage/failure modes, spalling occurs in the category of “Fatigue,” under both “Sub-surface-initiated fatigue,” and “Surface initiated fatigue.” Spalling damage is progressive and can indicate that a bearing has reached the end of its fatigue life.

Image credit: SKF Corporation

Fretting

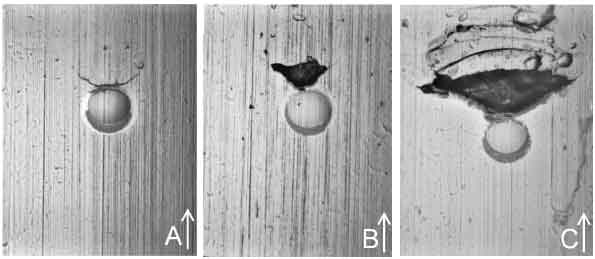

Image credit: NTN Corporation

A type of frictional corrosion, fretting is caused by microscopic oscillating motions (vibrations) between the bearing surfaces. Fretting is a subtype of the “Corrosion” mode of damage/failure, and is often referred to as “fretting corrosion” because it produces fine, metallic particles that can oxidize, like rust. Because of these metallic particles, fretting is abrasive and will quickly worsen the symptoms of damage.

False brinelling — considered a type of fretting — produces distinct depressions in the bearing raceway that look similar to true brinelling. It is typically caused by vibrations that occur when the bearing is in a static state, and therefore the depressions caused by false brinelling will have the same spacing as the rolling elements.

Feature image credit: JAD Associates

Leave a Reply

You must be logged in to post a comment.