It’s expected that a ball screw, with metal-on-metal rolling contact between the balls and the raceways, will require periodic lubrication with either grease or oil. One of the advantages that lead screws have over ball screws is that they can often operate without lubrication — eliminating maintenance and the potential hazards that come with using grease or oil: contamination of the process or the environment, storage of the lubricant, and the attraction of particulates to the assembly. But just because some lead screws don’t require lubrication, doesn’t mean that lubrication should never be used. In fact, in some lead screw applications and operating conditions, lubrication can benefit both performance and life.

It’s important to note that the “zero maintenance” benefit of lead screws applies to those that use a plastic or polymer nut. Bronze nuts, which are used for higher load capacities and, in some cases, better corrosion resistance, always require lubrication, since they involve metal-on-metal sliding contact between the screw and the nut.

But plastic or polymer nuts, which make up a significant portion of lead screw applications, have self-lubricating properties — that is, lubricants are impregnated into the nut material and are released as the nut and screw slide across one another. However, internal lubricants aren’t released consistently, and this fluctuating level of lubrication can cause uneven operating torque and wear. Externally applied lubrication remedies this problem by ensuring a more consistent application of the lubricant.

External lubrication also reduces friction, which can be significant in lead screw operation due to the sliding contact between the screw and the nut. This is especially critical for lead screw assemblies that are preloaded, as preload increases the contact, and therefore, the friction, between the screw and nut.

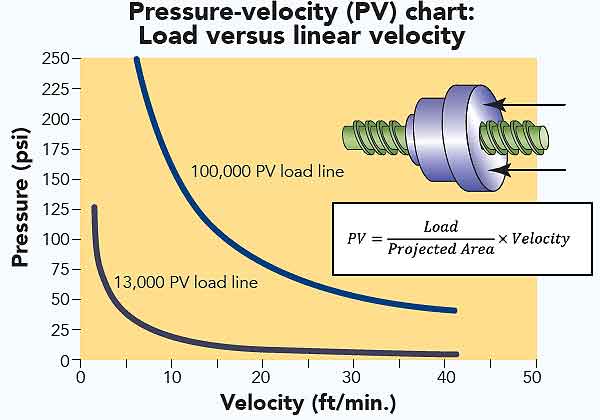

One of the key criteria for sizing and selecting a lead screw is its PV rating, which is the highest combination of pressure and velocity the screw and nut can withstand. The PV rating depends on the amount of heat generated as the screw and nut surfaces slide against one another.

Since lubrication reduces friction and heat generation, manufacturers often provide PV ratings that assume a grease film or dry lubricant is present. Be sure to check with the manufacturer if the PV rating doesn’t indicate whether external lubrication is assumed.

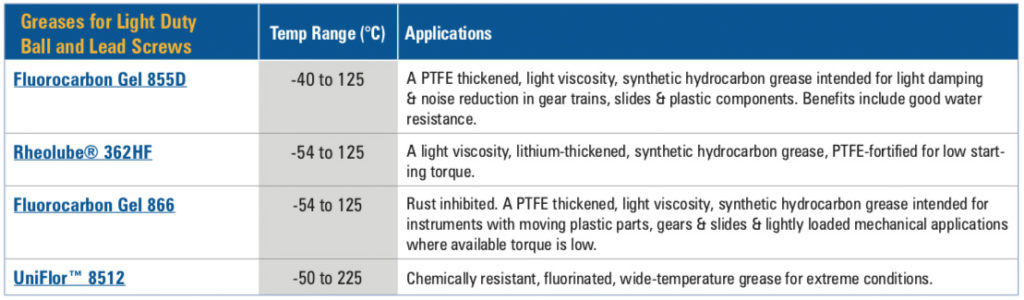

When external lubrication is deemed beneficial, the designer or engineer can choose between grease/oil or a solid lubricant. If grease or oil is chosen, there are formulations suitable for lead screw applications that require high travel speeds, clean room compatibility, and a variety of temperature ranges. But keep in mind that these lubricants, particularly grease, can attract and trap dust and other fine particulates that are abrasive to the lead screw assembly and can reduce the life of the screw and the nut.

Image credit: Nye Lubricants, Inc.

The term “solid lubricant” usually refers to a PTFE-type coating (known under the brand name, “Teflon”), which is by far the most popular solid lubricant for lead screws. Some manufacturers offer their own proprietary formulations, but most use PTFE as the primary lubricating component. Solid lubrication is typically applied by the manufacturer with a spray method to achieve a very precise, even thickness, and then cured.

Image credit: AMETEK, Inc.

Solid lubricants provide better protection than oil or grease against liquid contamination — water, acid, or alkaline — and often permit a wider range of operating temperatures. They are also the best option in situations where grease and oil are not allowed, such as medical and optical applications. While the friction coefficients of solid lubricants are higher than those of grease or oil (PTFE has a friction coefficient range of 0.06 to 0.12), the coefficient of friction remains constant regardless of preload or applied load, which ensures consistent torque requirements and smooth operation over the life of the lead screw.

Feature image credit: Helix Linear Technologies, Inc.

Leave a Reply

You must be logged in to post a comment.