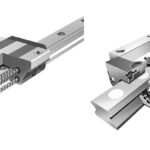

Crossed roller guides are non-recirculating linear bearings whose rollers are oriented in a “crisscross” pattern (each roller is turned 90 degrees relative to the one next to it) and move between two parallel guides with V-shaped grooves. Because the rollers don’t recirculate, these guides provide high load capacity and good stiffness, with smoother motion than their recirculating bearing counterparts.

Image credit: Nippon Bearing

Like the ball cage designs of some recirculating linear guides, crossed roller guides also use cages to contain the rollers, prevent metal-to-metal contact between them, and control their movement. Some crossed roller guides use cages made of metal, which hold the rollers in two places (top and bottom). Metal cages offer protection against contamination, and they’re suitable for vacuum, cleanroom, and high-temperature applications.

But metal cages take up significantly more space than designs made of resin or engineered plastic, which can be molded to fit the rollers more closely, allowing more rollers to be used in a given length. Plastic or resin cages also allow more of the roller to be exposed for contact with the raceway, which increases load capacity as well.

Image credit: IKO Nippon Thompson

Regardless of the type of cage, crossed roller guides can experience what is termed “cage creep.” Because the two guides move relative to each other and the cage “floats” between them, over time the cage can move, or creep, from its intended center position. This is especially common in vertical applications, applications where the slide makes only partial strokes (not the full length of the guide), or when the application involves uneven loading or high acceleration and deceleration.

When the cage moves from its center position, the slide’s stroke length is likewise reduced, and the cage will hit the rail end stop when the attempted movement exceeds the new, shortened stroke length. This causes the cage — and therefore, the rollers — to slide, or skid, as it’s forced back to its center position. And when components slide rather than roll, friction, heat, and wear increase. Torque required from the motor also increases, causing torque spikes at the end of travel.

There are two types of mechanisms that can prevent cage creep in crossed roller guides. One such “anti-creep” design uses a rack and pinion system — mounted internally or externally to the guide — to maintain the correct position of the cage.

Image credit: SKF

The other common anti-creep design uses a studded center roller that engages with indentations machined into the rail surface to ensure the cage stays in the correct position.

Image credit: Nippon Bearing

With an anti-creep mechanism, crossed roller guides can be used in applications with unevenly applied loads or with very high acceleration and deceleration, and in vertical mounting configurations, without a loss of travel or of load carrying capacity.

Leave a Reply

You must be logged in to post a comment.