Linear guides provide accurate, high-capacity travel for a wide variety of machine types and processes. In the most demanding applications, linear position feedback is often needed in order to ensure the tool, gripper, or workpiece follows an exact path or reaches a precise position. In these cases, design engineers can choose to add a linear encoder to the motion system, or they can use a linear guide with an integrated measuring system.

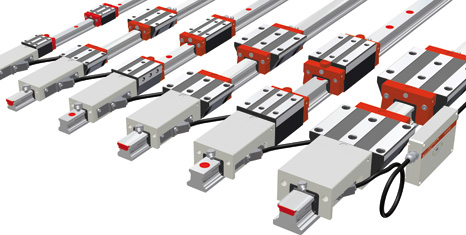

Image credit: SCHNEEBERGER

How does it work?

An integrated linear measuring system is very similar to a conventional linear encoder, but with the scale mounted onto the rail and the read head mounted onto the carriage. Integrated systems are often based on magnetic or inductive encoders, rather than optical versions, because these technologies are less sensitive to dust, debris, and liquid. They are also able to tolerate some variation in gap between the sensor and the scale, which can occur if the system experiences shocks or vibrations. But with modern magnetic and inductive technologies that can provide resolution down to sub-micron levels, users aren’t sacrificing performance by choosing integrated measuring systems over optical encoders.

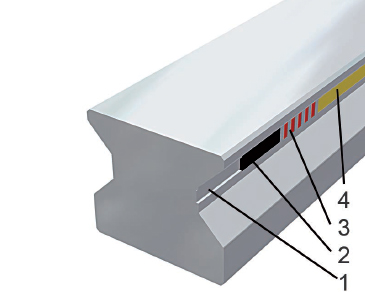

Integration of the measuring system covers both parts—the scale and the read head. The scale is conventionally mounted in a groove that is machined into the side of the rail. The scale is protected by a laser-welded cover, which provides a dust-tight seal and protection against water ingress (IP67 and IP68 ratings are common for integrated measuring systems).

Image credit: SCHNEEBERGER

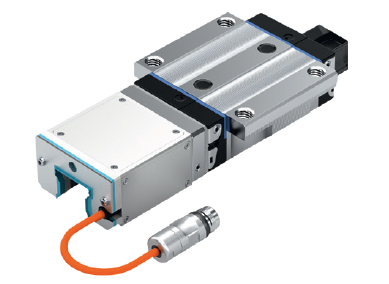

The read head is typically mounted either inside or onto a housing, which sometimes also contains the encoder’s electronics. The housing is mounted onto the end of the carriage, which increases the length of the carriage, but not the width. Although this means that a slightly longer rail is needed in order to obtain the same travel distance, the lack of added width beyond the sides of the carriage means that an assembly with integrated measuring can fit in the same footprint as a standard assembly, so retrofits are generally easy, and no special provisions have to be made for added space.

Image credit: Bosch Rexroth

What are my options?

Integrated measuring systems almost always come in incremental versions, regardless of manufacturer. And most suppliers also offer absolute versions, for applications where the operator needs to know the linear guide’s exact position after a power loss, or when re-homing after a power loss is not feasible. Like conventional linear measuring systems, incremental versions are provided with either analog or digital interfaces and absolute versions are commonly offered with SSI (Synchronous Serial Interface). For absolute encoders, options are also typically available for proprietary interfaces, such DRIVE-CLiQ (Siemens) or Fanuc Serial Interface.

What are the benefits?

When decision-time comes, the question may arise, “This sounds great, but I’m sure it’s more costly than buying the components separately. So why don’t I just source the components myself and get exactly what I want?” Beyond simplicity in ordering, there are several reasons to use a linear guide with integrated measuring.

First, it’s true that ten or fifteen years ago, integrated measuring systems were limited in options and compatibility. But now, with more linear guide companies offering integrated measuring systems, it’s almost guaranteed that you’ll find a system that meets even your most stringent requirements for resolution, accuracy, environmental protection, and length.

Second, with an integrated system, the hard part—mounting and alignment—is already taken care of. There’s no need for external mounting components and no alignment required. And in the interest of simplifying logistics and inventory, both for themselves and for their customers, linear guide manufacturers have ensured that while the systems are integrated, the components are interchangeable. That means that if a rail with linear scale needs to be replaced, the user doesn’t have to also replace the read head. And if the carriage is damaged, it can be replaced while the read head and electronics remain. Schneeberger, for example uses the same reading head for all linear guide sizes.

Finally, Bosch Rexroth points out that integrated measuring systems are, or can be, ready for Industry 4.0 applications. For example, in their IMS-A measuring system, Rexroth has included additional temperature and motion sensors that can be used to monitor operating conditions and form the basis for predictive maintenance.

Feature image credit: SCHNEEBERGER

Who sells these systems? I’ve found a few motorized options like those by Zaber, but I’m having a hard time finding an unmotorized version.

.