Image credit: THK Co., Ltd.

One of the differences between radial ball bearings and recirculating ball linear guides has historically been that radial bearings typically use a cage to separate the balls and control their movement, whereas profiled rail guides did not. But in the early 2000’s, manufacturers of profiled rail bearings began introducing versions with ball cages (also referred to as “ball chains” or “ball separators”) to improve bearing life, running characteristics, and noise. The incorporation of ball separators into ball screw nuts came a few years later, as manufacturers had to solve the unique design and material challenges posed by the more complex recirculation path the ball chain must travel.

Now, some manufacturers offer all, or most, of their profiled rail bearings and ball screw nuts with ball chains, and for many applications — especially those that can benefit from lower noise, smoother running, and less frequent lubrication — linear guides and ball screws with ball separators make sense. In many cases, manufacturers who offer pre-assembled and integrated systems, such as linear actuators or pre-assembled screw drives, use the ball chain versions of linear guides and ball screws by default.

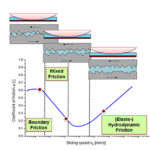

In any bearing, when the balls are free to roll (or slide) without the guidance of a cage or chain, they make contact with each other due to different speeds that occur as the balls enter and exit the load zone. This contact generates friction and audible noise. A ball chain prevents the balls from contacting each other reduces friction, and therefore, heat, which prolongs the life of the bearing or nut. Noise is reduced because the balls no longer make metal-to-metal contact with each other — instead, they make metal-to-polymer (or metal-to-resin) contact with the ball chain.

Image credit NTN-SNR

And reducing heat actually provides a two-fold benefit, because less heat also means less breakdown of lubrication. Lubrication is also retained and delivered in a more efficient manner thanks to the “pockets” created around the balls by the ball chain. These pockets trap lubrication and ensure better delivery of grease or oil to each individual ball.

Some manufacturers use ball chains in their “high-speed” series profiled rail bearings and ball screws, but the ball chain must be sturdy enough to withstand the forces caused by sliding and bending at these high speeds.

Providing consistent, set spacing between the balls also improves running characteristics by reducing variations in friction forces that occur when the balls are unevenly spaced (i.e. without a ball chain or cage). Consistent distance between the balls, together with more controlled movement, provides smaller variations in rolling resistance and better running smoothness. For applications that require extremely smooth running characteristics, using a profiled linear guide or ball screw with ball chain can be a good way to satisfy the application requirements without going to a more expensive technology, such as air bearings or linear motors.

Don’t confuse ball chains (aka ball cages) with spacer balls. Spacer balls are slightly smaller than the load-bearing balls and serve to reduce friction and noise when the balls make contact. But when spacer balls are added to a linear bearing or ball screw, some load-carrying balls must be removed, which means load capacity and stiffness are reduced.

Feature image credit: Schaeffler Group Inc.

Leave a Reply

You must be logged in to post a comment.